It’s taken me a while to get to this point with a standing rigging replacement, bottom paint and holidays in the middle of the task ...

I was finally able to suck all the fuel out of the tank and dry the inside, find proper disposal/ recycling of the excess fuel. I kept 15 gallons filtered in new cans to put back in eventually after the new tank goes in. (is that a good idea ?).

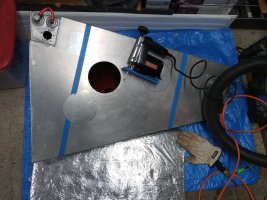

Now I just need to figure out how to get the tank out . The good news is that I can “rock” the empty tank with the supports removed , so I’m thinking if I can just get all the hoses and wiring off, it will just lift out .

Any suggestions on how to remove the large filler / vent hoses on the side with little clearance (see lower left side of the tank in this picture) ? Those hose doesn't come off easy. Next, I am going to try to use a small screwdriver to wedge in between the hose and it's fitting on the tank.. Some will say I should just cut the hoses and replace them, but I don't think that will be straightforward becase the hoses are hidden behind the interior and obviously have a signficant bend in them to reach the deck fitting.

PS. for those interested (and I may have mentioned this in this post already). The guy in Costa Mesa who made this original tank for Ericson (

Berry Tanks) is going to make me a new tank in his shop. I just need to drive the old tank to SoCal. I think it will be worth it.

ericsonyachts.org

ericsonyachts.org