chris85green

Member I

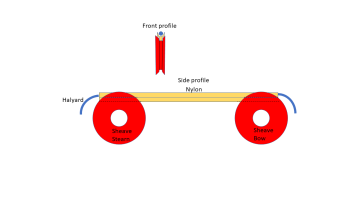

Hello all, this is my first post on this site. My name is Chris and I own a '79 Ericson 35-2. I went up the mast recently to try and get my halyards moving again, one has ball stops that got jammed in the sheaves and the other halyard line broke. Both are spliced line to wire. Once up there it was evident that the sheaves are trash, they do not move and it doesn't look like getting them to move is a likely option. I called the boatyard today and it will be $1000 for unstepping and stepping plus $15/day to work on my mast (Ventura). For now, I have the jib halyard up since i was up there i just hauled it up manually and fed the line through the masthead myself as the new 8mm dyneema jammed trying to get through the groove that is apparently fit or has worn to the wire diameter. My pirmary question here is this, I will me taking down the mast but i dont have the funds or time to do all of that right now, and I had a thought. Could i run a piece of high density nylon with a bottom profile that matches the wire groove and a top profile that would allow the dyneema line to run over the top of the two sheeves, so then the rope would just run over the top of them with minimal friction? Obvioulsy working sheaves would be far better and less potential wear on the line but until i take it down its $18 for the HD Nylon and $150 for a new line. with this Id think i can at least run my main up and down a few times until early 2023 when i can pull the mast. I have attached a little diagram for a visual.

Second question, what is the size of the old E 35-2 Sheaves and Pin? I wanted to swap them while the mast was up but it seems with the rigging in the way thats unlikely. So maybe I can order them in advanced and not pay for so many lay days. Thanks in advance for any help!!

Second question, what is the size of the old E 35-2 Sheaves and Pin? I wanted to swap them while the mast was up but it seems with the rigging in the way thats unlikely. So maybe I can order them in advanced and not pay for so many lay days. Thanks in advance for any help!!