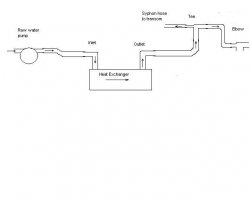

I made it up to work on the boat today and took some pictures. Rob, your diagram is exactly the set up I have (same as Loren's). The attached picture is of the same "T" as Loren pictured, but I have the camera below the fitting looking up.

Your comments " ,,interesting a great lakes boat (Brian's) has clogging in the elbow and probably h.e. as well. And pin hole corrosion in the elbow. Unusual? Prior salt water history? Do pencil zincs last longer in fresh water?"

Yes, this was a salt water boat until the summer of 2007.

Yes, zincs do last longer in fresh water; magnesium anodes are appropriate for fresh water, I use them on the shaft but have never been able to find one for the pencil anode in the HE.

I had removed the end of the HE and drained the H2O that way but could not get a real good look at the HE condition. Today I took it off and it has a little bit of deposits on 1/2 of it so I'll have it cleaned. Overall it wasn't bad at all.

Paul, yes I remember corresponding with you and I thank you for your offer. With your input to the location of the muffler I was able to finally locate mine - it's below the level of the lazarette locker floor in probably the most inaccessable area on the boat!! But after removing the hot water heater and the shelf it sits on, I moved some hoses and wires and was able to get a fair view of the muffler. It looks to be in good shape and no signs of any leaking.

Since the exhaust system is disconnected right now and I can't simply start the engine to re-winterize the muffler, I had to do something different. Using my shop vac I first blew out any water in the system. Then I poured a gallon - about a quart at a time - into the open end of the exhaust hose (where the riser elbow connects to the hose) and blew that through. I am confident the muffler is now fully winterized. The second picture attached shows the open end of the HE and the exhaust hose into which I poured antifreeze. This picture needs to be rotated 90 degrees clockwise for proper viewing.

Wow, so who would have know that you could "winterize" the raw water system, see antifreeze come out the end of the exhaust, but still not have antifreeze in the HE or muffler. You all have been a tremendous help sorting this out. Thanks.

Now I just need to find a radiator shop that can give my HE a good cleaning and I need to locate the Onan style H20 injection elbow with 1 1/2" pipe thread input, 5/8" raw water input, and output to fit inside my 1 5/8" ID exhaust hose,,,, no easy task!