Pat & Ed

I agree, that's why I bought the 38-200 because she's offshore capable, plus I'm an Ericson freak considering I've owned the 27 & the 35 MKII.

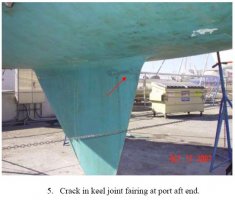

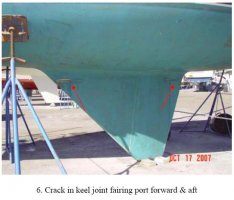

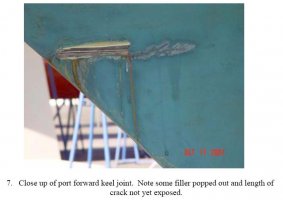

But I found out that it was not uncommon for the later Ericson's 88 & 89? to not have the hull mold releaser wax removed. Thus the keel flex. Considering that this is turning into an expensive repair, I'm thankful the insurance company is picking up the tab, but she should be better than new when they are done.

Thank you for the words of encouragement!!

Are you the folks doing the HaHa?

Jay

I agree, that's why I bought the 38-200 because she's offshore capable, plus I'm an Ericson freak considering I've owned the 27 & the 35 MKII.

But I found out that it was not uncommon for the later Ericson's 88 & 89? to not have the hull mold releaser wax removed. Thus the keel flex. Considering that this is turning into an expensive repair, I'm thankful the insurance company is picking up the tab, but she should be better than new when they are done.

Thank you for the words of encouragement!!

Are you the folks doing the HaHa?

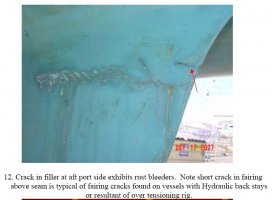

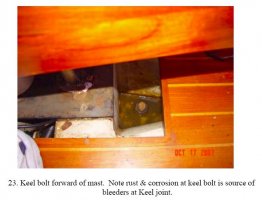

Jay