Kevin Johnston

Member III

I am in need of replacing my boom on my E27. Last time out I was flying a new North kevlar reinforced main and it was to much sail for my old bloom and the boom was folded in the middle. But boy did it make the boat go!

Is the spar with the same profile still available? I know I saw the profile in a catalog awhile back but I haven't find it since. Do you have any recommendations for a manufacturer to turn to for new stock?

Any recommendations for a used but similar could work to? (I checked Second Wave in Seattle and some riggers but no luck yet on the used side)

I am frequently out in the Straits of Juan de Fuca in the thick, so would it be worth the expense in buying something larger/stronger than the original?

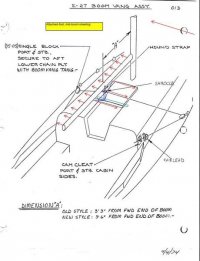

I like the idea of rerigging the main sheet to the stern instead of over the companionway. From a leverage standpoint it would seems that it is a compromise to have the main sheet attached in the first 1/3 to 1/2 of the the length of the boom. Would there be a need for a traveler if the main sheet was mounted aft?

Thank you,

KJ

Is the spar with the same profile still available? I know I saw the profile in a catalog awhile back but I haven't find it since. Do you have any recommendations for a manufacturer to turn to for new stock?

Any recommendations for a used but similar could work to? (I checked Second Wave in Seattle and some riggers but no luck yet on the used side)

I am frequently out in the Straits of Juan de Fuca in the thick, so would it be worth the expense in buying something larger/stronger than the original?

I like the idea of rerigging the main sheet to the stern instead of over the companionway. From a leverage standpoint it would seems that it is a compromise to have the main sheet attached in the first 1/3 to 1/2 of the the length of the boom. Would there be a need for a traveler if the main sheet was mounted aft?

Thank you,

KJ

Last edited: