Mike Thomas

Member II

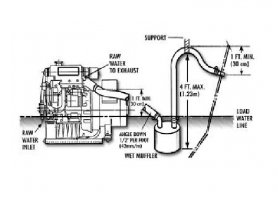

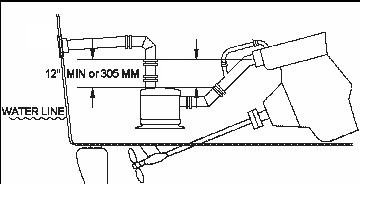

I am replacing my old water jacket type of muffler with a Water lift muffler in my 76 E-29. I have piped the exhaust in the same configuration as the water jacket and will locate the Water Lift muffler in the port cockpit locker. The muffler will sit at about the waterline. I have piped the exhaust well above the waterline before the muffler and can do the same with exhaust after the muffler but I am wondering if that makes sense. My thinking is that if I'm having a problem starting, I will still be pumping water into muffler as it cranks and never build up enough exhaust pressure to blow the water out. I would think that I don’t want an exhaust system where the "in" (engine side) of the muffler is lower than the “out” side of the muffler. In theory, if I kept cranking and never started, I would fill up the muffler then exhaust manifold before the water started to pump out of the exhaust port.

The interesting thing is that I’ve never seen this issue ever addresses. All of the diagrams that I have seen show what I think is a bad design (if the engine doesn’t start). One article mentioned that there is a drain plug that can be opened in the event of hard starting but that would be difficult.

I would think that the only reason for having the “out” side of the muffler piped higher than the “in” (engine) side, is to keep a following sea from getting in the engine but if the “in” side of the muffler is piped higher than the “out” exhaust port, that should not be a problem.

Am I thinking correctly here?

Mike Thomas

E-29 Babylon NY

The interesting thing is that I’ve never seen this issue ever addresses. All of the diagrams that I have seen show what I think is a bad design (if the engine doesn’t start). One article mentioned that there is a drain plug that can be opened in the event of hard starting but that would be difficult.

I would think that the only reason for having the “out” side of the muffler piped higher than the “in” (engine) side, is to keep a following sea from getting in the engine but if the “in” side of the muffler is piped higher than the “out” exhaust port, that should not be a problem.

Am I thinking correctly here?

Mike Thomas

E-29 Babylon NY

Harold

Harold