davisr

Member III

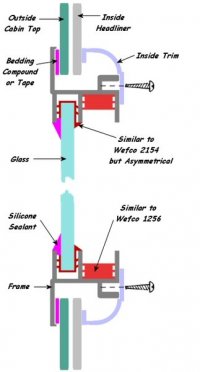

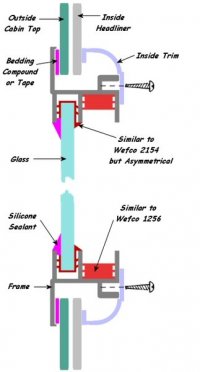

I'm wanting to hang on to my original aluminum-framed portlights with tempered glass. I plan to rebed the portlights to the exterior of the cabin with butyl tape. This question does not concern that part of the job. Instead it concerns the gasket that holds the glass within the frame. I want to avoid a complete rebuild of the portlights, since the Wefco gaskets are not cheap, and it's not very easy getting everything back together. A recent thread addresses this difficulty http://www.ericsonyachts.org/infoex...11765-Leaky-windows-on-a-1978-27-foot-ericson I read on an older thread a posting by Tenders, who was advised by a specialist, that it is preferable to avoid this disassembly and instead to apply Dow Corning 795 Silicone to the joint between the glass and the gasket http://www.ericsonyachts.org/infoex...Ericson-27-remove-clean-and-re-bed-portlights My question is this: Has anyone ever used 795 Silicone to seal this joint, and if so, you have had any success? Attached is a drawing by a fellow E25 owner of the profile of the E25 portlight. I believe this is the same or similar to that of the E27 and E29. Thanks, Roscoe.