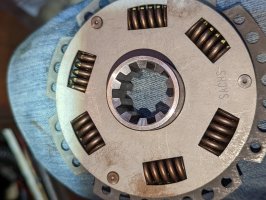

1. Process of getting to the damper: I wanted to mention that getting to the damper requires removing the bell housing, which requires room to slide it back. On many forums I have read about the lack of space and inability to move the prop shaft. One solution is to raise the engine and slide it forward (I have done this when I rebuilt the head). Typically others have made a vertical hoist of some type. I tried something I have only heard about and was really stoked when it worked. First the engine mount 15/16" nuts were backed off. Then the prop shaft was disconnected. I took a dock fender, deflated it, stuffed it under the oil pan longitudinally, and then slowly re inflated with a hand bike pump. The engine responded by rising. Then the rear engine mount nuts were totally removed, more pumping, and I had gained about 2" of clearance above the PSS. Off came the bell housing bolts and the transmission and bell housing were jointly slid aft. Access to the worn damper was now possible. 8 more loosened screws were removed and the errant part was out. I have now successfully re assembled the engine and should have a test run in the next two days.

2. Kamell, an acquaintance who has a Valiant 40, and has been cruising over the last 5 years, has had this same damper plate failure. He saw the pictures I had sent him. He said that his engine had the same damper, the wear on the splines was a lot worse, the springs had been worn flat along one side, and the bell housing was full of iron dust and spring shards. He has a 40 HP Perkins.