I wonder if it's possible to pump any useful amount of insulting foam behind there... The V-berth gets freakin cold in the winter! For now, I've lined the sides with 2-inch thick foam cushions to create a nice padded "nest" area. But it does cut down on the width of the berth.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Preparing my 43 year old 29 for extended (indefinite) cruising

- Thread starter Thursty30

- Start date

If it works, good.

Sometimes, though, elements were designed to float, just so as not to bind when the boat flexes.

A tight cabin sole, for instance, is what makes some of our boats squeak like crazy going to windward.

Same reason portlights aren't installed into tight holes in the cabin house. Hard and against hard means something's gotta give.

So, incorporating a little flexibility--caulk, not epoxy--can sometimes be wise.

Sometimes, though, elements were designed to float, just so as not to bind when the boat flexes.

A tight cabin sole, for instance, is what makes some of our boats squeak like crazy going to windward.

Same reason portlights aren't installed into tight holes in the cabin house. Hard and against hard means something's gotta give.

So, incorporating a little flexibility--caulk, not epoxy--can sometimes be wise.

Last edited:

The hatches are another issue. They may be a little different on newer boats. But my hatches are not remotely water tight, which is something that I would like to rectify. I've seen Web Chiles videos of him pounding across the sea in his Moore 24, with six inches of water sloshing around on the sole and another 3 or four inches on the leeward settee. :0 No thank you.

First, the main hatch looks like a problem. When I first saw the boat, I thought that must be some crude DIY job of the previous owner. But no... that's just the way it came from the factory. A wood box and a piece of frosted plexiglass. While I suppose it could be made water tight with some gasket material, there are no proper dogs - only four little #4 screws holding the latch down. And it's an odd size - 24" x 18" or so. I haven't been able to find any kind of standard hatch that would be a bolt-on replacement. Looks like a major fiberglass job to fit any other hatch in there. And I'm not completely sure there is room in front of the bulkhead - again, later boats have a slightly different bulkhead placement. I suppose a better hatch could be built, with proper dogs, to fit the existing opening. I haven't gone there yet.

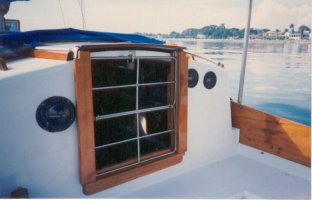

Second, the companionway. As noted previously, the sill is too low for safety. The drop-boards leak. And my boat came to me without a sliding hatch, so there's just a temporary one that I made. Which would work better with a sea hood. And a dodger would keep the rain off the hatch boards. Which is the conventional path that I had been heading down. But last year, I saw a few retrofits of the companionway with watertight hatches like this one:

Still thinking about it. That particular mod wouldn't work for a tiller-steered boat, but I've seen a similar one that would. (Darn... if I copied those pics, I've since lost them.)

On the other hand, if I seal up my hatches well, then I'll have to add ventilation and a couple of proper dorade boxes! (BTW: The stock cowl vents for the Atomic 4 probably need dorades added.)

One other thought on the subject of hatches: I've seen some people, such as James Baldwin recommend having steel bars made up for all the hatches, as a security precaution. That would probably also require a steel frame to hold them. Instead of the strip of teak that holds the drop boards, for example

First, the main hatch looks like a problem. When I first saw the boat, I thought that must be some crude DIY job of the previous owner. But no... that's just the way it came from the factory. A wood box and a piece of frosted plexiglass. While I suppose it could be made water tight with some gasket material, there are no proper dogs - only four little #4 screws holding the latch down. And it's an odd size - 24" x 18" or so. I haven't been able to find any kind of standard hatch that would be a bolt-on replacement. Looks like a major fiberglass job to fit any other hatch in there. And I'm not completely sure there is room in front of the bulkhead - again, later boats have a slightly different bulkhead placement. I suppose a better hatch could be built, with proper dogs, to fit the existing opening. I haven't gone there yet.

Second, the companionway. As noted previously, the sill is too low for safety. The drop-boards leak. And my boat came to me without a sliding hatch, so there's just a temporary one that I made. Which would work better with a sea hood. And a dodger would keep the rain off the hatch boards. Which is the conventional path that I had been heading down. But last year, I saw a few retrofits of the companionway with watertight hatches like this one:

Still thinking about it. That particular mod wouldn't work for a tiller-steered boat, but I've seen a similar one that would. (Darn... if I copied those pics, I've since lost them.)

On the other hand, if I seal up my hatches well, then I'll have to add ventilation and a couple of proper dorade boxes! (BTW: The stock cowl vents for the Atomic 4 probably need dorades added.)

One other thought on the subject of hatches: I've seen some people, such as James Baldwin recommend having steel bars made up for all the hatches, as a security precaution. That would probably also require a steel frame to hold them. Instead of the strip of teak that holds the drop boards, for example

Hatching a solution

On the hatch question...

Note that larger boats (over about 22 feet, give or take) from the 60's and 70's had teak framed hatches with an acrylic lens screwed down into a bed of sealant on top. At the time this was acceptable for blue water boats like the Valiant 40, even. I have friends that blue water cruised their V-40 for ten years after upgrading their original hatches with Lexan lenses. No problems.

The Ericson 27, 29, and 32-2 (to list some the smaller designs) were all built to this Teak standard of strength.

Sidebar: I sometimes wonder if we've all become a bit mesmerized by shiny alloy hatches! No varnishing!!

No varnishing!!

When choosing how to rebuild and re-watertight an old hatch, one way is to reproduce the original design, probably with an improved sealing double-flange at the top of the frame.

Some folks just assume that the original design is inadequate solely due to age, but perhaps not.

Often it's just old and worn out and needs a replacement or total rebuild. Somewhere on this site are some pix of the teak replacements that Martin King built with expert craftsmanship. IMHO those are the equal of any of my Lewmar's.

If you want a 'modern' alloy frame replacement hatch, carefully measure your "cut out" dimensions and start searching the internet. There are some hatch makers that are more common here, and some you might have to search out from other countries.

And some just do not advertise nearly as much as do others.

Regards,

Loren

On the hatch question...

Note that larger boats (over about 22 feet, give or take) from the 60's and 70's had teak framed hatches with an acrylic lens screwed down into a bed of sealant on top. At the time this was acceptable for blue water boats like the Valiant 40, even. I have friends that blue water cruised their V-40 for ten years after upgrading their original hatches with Lexan lenses. No problems.

The Ericson 27, 29, and 32-2 (to list some the smaller designs) were all built to this Teak standard of strength.

Sidebar: I sometimes wonder if we've all become a bit mesmerized by shiny alloy hatches!

When choosing how to rebuild and re-watertight an old hatch, one way is to reproduce the original design, probably with an improved sealing double-flange at the top of the frame.

Some folks just assume that the original design is inadequate solely due to age, but perhaps not.

Often it's just old and worn out and needs a replacement or total rebuild. Somewhere on this site are some pix of the teak replacements that Martin King built with expert craftsmanship. IMHO those are the equal of any of my Lewmar's.

If you want a 'modern' alloy frame replacement hatch, carefully measure your "cut out" dimensions and start searching the internet. There are some hatch makers that are more common here, and some you might have to search out from other countries.

And some just do not advertise nearly as much as do others.

Regards,

Loren