While I can't help with anything specific to the 38 .. here's how the same went on my 32 last month.

I used a reputable rigger local to my marina that would allow my help in the process. The standing rigging and halyards were replaced a few years ago (by P.O.) but it was clear the mast would benefit from stripping & inspecting. I pulled off the tangs, spreaders, winches, stays/shrouds and halyards. The antenna was shot and the wiring & lights looked to be original, so it all came off. I cleaned up all the stainless pieces, inspected the bolts and clevis pins, scrubbed the mast with 3M pads and rebuilt the winches. I couldn't afford to paint the mast, but wish I could have. While cleaning up the spreaders I could see that the ends were pretty corroded. After having the rigger inspect them, we cut off about 5/16" of each to get clean ends. I decided to rewire the electrical and coax. We put in a conduit and riveted it to the mast. I had the masthead wired for a Tri-color, but put in a standard anchor light for now (due to the cost). We removed the existing steaming light, put a plate over the hole and drilled an opening for a steaming/deck light combo lower near the bottom spreaders. I also decided to have the halyards put internal. I reused the wire/spliced to rope halyards because they are almost new. I would .. or will go to all line next time. It required quite a bit of drilling and hogging out at the masthead, but came out great.

All the cleaned up parts were assembled with tel-gel and the winches were mounted using heavy tape beneath. Back on the boat, I pulled all the chainplates, cleaned them up, had them inspected and re-installed.

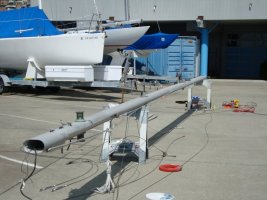

The best part of the deal was a used boom and rigid vang the rigger gave me from a Catalina 320. It was allot of work to change out, but a very noticeable improvement in the 40 mile race last week that was our shake down.

The job overall got expensive, as I changed out my foil for a furler too .. but the piece of mind and performance is worth it to me.

Good luck on yours. Be careful of the question; Can I ? .. it gets to the pocket book.

Regards, Greg