Tom knows this already, but for the record:

A brief

blog entry.

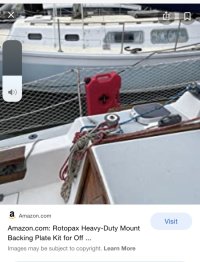

A 2x4 between stanchions is the shortcut, but puts the jugs a bit in the way and subject to dousing. I built deckhouse racks for 32-3 and 381 to raise them up and bit and out of the wy, and they worked such that only small adjustments were made in three Hawaii voyages.

I used 1/2" exterior plywood and Gorilla glue and drywall screws, then house paint. Entirely expendable. However, despite living in a dusty shed for three years--the racks, not me--I found the 2017 version was still ready to go for 2021.

Padding at deck contact is hardware-store pipe insulation, either placed on the grab rail or glued to the bottom of the rack. The "design" relies on a cantilever out from the deckhouse and then vertical support from the stays, with lashings to keep everything in place. Trial and error install reveals the compromise and placement of battens necessary for the proper sit and fit.

It's not rocket science. If interested the racks are on continuous display in my three Hawaii videos. (I have a standing apology on file for putting diesel into red cans instead of yellow, consider it invoked here).

E32-3 racks

View attachment 42338...

View attachment 42339...

View attachment 42341

E381 racks

View attachment 42340