I present to you my recently acquired 1973 Ericson 27. As a first-time, totally misguided, and overly optimistic boat owner, I figured she just needed a little TLC to get her rollin'.

Apart from two frozen winches, a busted portlight, a steady leak at the prop shaft and the termite-ridden companionway hatch, I didn't really notice any serious issues... hah! Yeah well, the stanchions were a bit loose and the cockpit floor was slightly spongy, but those were going to be quick n' easy fixes, right?

And so goes this important rule of thumb, which I'm sure you've already heard around here: factor at least 10 times the amount of time you thought you were going to spend repairing your boat plus double the dinero. Also, just keep telling yourself it's a labor of love and make sure you search this forum for loads of invaluable advice on how to do it all!

She looks alright at first sight, don't you think? Well, think again:

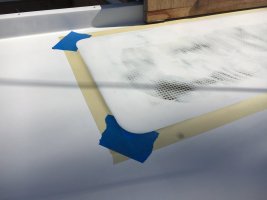

In essence, core rot (and sole delamination) happens when the impermeability of the outer fiberglass shell of your boat is compromised by an improperly sealed fixture for example, subsequently allowing water to percolate down into the underlying core (usually made of wood but sometimes foam) and then causing it to become soft. At this point, the core no longer provides any structural support (i.e. for a stanchion mount or your heavy auntie) and must thus be replaced.

Apart from two frozen winches, a busted portlight, a steady leak at the prop shaft and the termite-ridden companionway hatch, I didn't really notice any serious issues... hah! Yeah well, the stanchions were a bit loose and the cockpit floor was slightly spongy, but those were going to be quick n' easy fixes, right?

And so goes this important rule of thumb, which I'm sure you've already heard around here: factor at least 10 times the amount of time you thought you were going to spend repairing your boat plus double the dinero. Also, just keep telling yourself it's a labor of love and make sure you search this forum for loads of invaluable advice on how to do it all!

She looks alright at first sight, don't you think? Well, think again:

In essence, core rot (and sole delamination) happens when the impermeability of the outer fiberglass shell of your boat is compromised by an improperly sealed fixture for example, subsequently allowing water to percolate down into the underlying core (usually made of wood but sometimes foam) and then causing it to become soft. At this point, the core no longer provides any structural support (i.e. for a stanchion mount or your heavy auntie) and must thus be replaced.

Attachments

Last edited: