Tooluser

Flǎneur

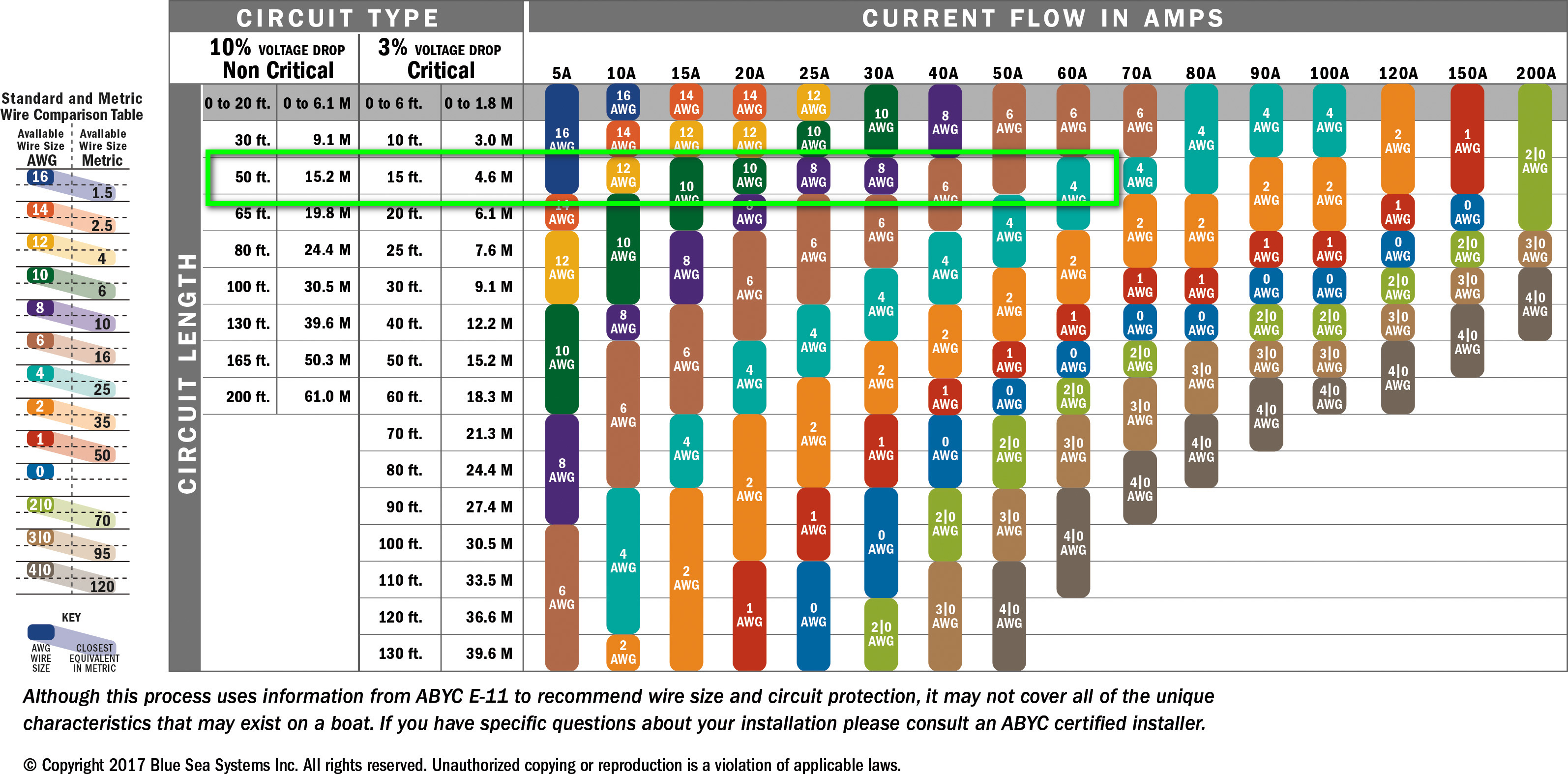

S/V Nobody has a bow windlass. Historically (and stock for the E38) it was powered by a lead-acid battery located in the bow. This battery can be ganged to the house bank (and thus the alternator, theoretically) by a switch for charging over a long (~50’ round trip) pair of relatively thin (#8 or #10 AWG) wires.

Current situation, with a dead windlass battery.

The battery in the bow is currently dead. How should I replace? The dollar cost ends up approximately the same. Anything I'm not considering?

A few salient facts:

Cost: $250-300 with a DC-DC charger.

Time: 5/5

Pro: Sail more.

Cons: Stay heavy in the bow. Replace the AGM every N years. Will a charger do a good job over that distance/voltage drop? Probably, with reasonable fiddling. (I'd buy an Orion.)

Cost: $350 with a DC-DC charger

Time: 5/5, easy

Pro: Lose a lot of weight (70lbs, and up high) in the bow. Battery lasts much much longer.

Con: Lithium hassle.

Time: 3/5 pulling fat heavy cables

Pro: Lose all the weight in the bow, no battery to wear out

Con: All that work. Gods know what else I’d find, too.

Current situation, with a dead windlass battery.

The battery in the bow is currently dead. How should I replace? The dollar cost ends up approximately the same. Anything I'm not considering?

A few salient facts:

- I have run this windlass over the AWG 10 cable, gingerly, even with the ‘dead’ battery. It worked fine! I was a bit surprised. Yes it has OCP. It’s possible it’s #8 or #6. But still not ideally sized for full-time running off the engine/house.

- The windlass should be considered a 100A load. Seawolf.

- The anchor has a significant amount of chain, but an AGM battery is 80 pounds so don’t be telling me this battle doesn’t matter.

- Replace battery in situ with AGM. Potentially add DC-DC charger to keep it topped up rather than just ganging them all together.

- Replace battery with Lithium, add DC-DC charger for the purpose.

- Remove battery, replace small cables with #2s.

Options Detail

Replace with fresh AGM

This wins on simplicity. Toss the old one, get a new one.Cost: $250-300 with a DC-DC charger.

Time: 5/5

Pro: Sail more.

Cons: Stay heavy in the bow. Replace the AGM every N years. Will a charger do a good job over that distance/voltage drop? Probably, with reasonable fiddling. (I'd buy an Orion.)

Replace with Lithium

Lithium batteries capable of the necessary cranking amps do exist. A 50Ah battery would be plenty. That said, this is a slightly experimental approach.Cost: $350 with a DC-DC charger

Time: 5/5, easy

Pro: Lose a lot of weight (70lbs, and up high) in the bow. Battery lasts much much longer.

Con: Lithium hassle.

Replace with #2AWG cable

Cost: $225 worth of cableTime: 3/5 pulling fat heavy cables

Pro: Lose all the weight in the bow, no battery to wear out

Con: All that work. Gods know what else I’d find, too.

Decision Matrix

| Option | Cost | Time | Pro | Con |

|---|---|---|---|---|

| New AGM | $350 | 5/5 | 0/5 | 4/5 |

| New Lithium | $350 | 5/5 | 2/5 | 2/5 |

| Pull the cables | $250 | 2/5 | 3/5 | 3/5 |

Just teasing!

Just teasing!