@Pete the Cat - Ray, the sole is still out so I checked today and nada on wires through the bilge/TAFG.

This photo shows the old common bar (bus?) in our boat to which the 12 ga purple wire was attached. There are at least 4 purple wires, and they're a very dark purple. There are also black lines attached to this bar. Maybe they had lots of dark purple 12 ga in 1986 and used that as black. Mabye by 1989 they got a deal on a palette of gray 14.

I'm convinced the wiring diagram is like the Pirates Code:

It's a useful starting point, but . . .

@peaman - Steven, there is one

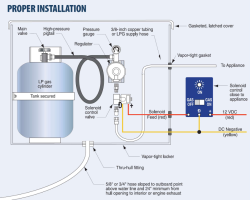

true purple colored wire and it is connected to the water pressure breaker. Thanks for the wire load data. The instructions call for a 1a fuse so I don't think the whole system draws much. With my new found multi-meter confidence I'll check the voltage at the solenoid when installed.

The electronics folks put a fuse panel in when they installed the the radio, AIS, and chartplotter.

There are two empty slots, but I don't know how many they will need for the radar. I can always install another or put an inline fuse in. I wish they'd installed a bigger one.

If the Trident control has an on/off button, it seems redundant to have an additional switch. By pulling power out of the panel area I will already disable the LPG controls when the battery switch is off. Is there a compelling reason for adding an additional switch?

Yes, our stove is a three burner Force 10. Thanks for the heads up on the stove battery.

@Loren Beach - I checked with an EE friend today and he confirmed there shouldn't be a safety problem using one wire bigger than the other as long as the smallest one still is adequate for the circuit's needs. He said it may not be strictly kosher for ABYC standards. As Steven said, "We do what we can." I'll be sure and label them. I can't find any guidance on what color the gas wiring should be so I'm using brown and will label them at both ends.

I think I have a clear path forward with wiring now. Thanks guys.