Hi There,

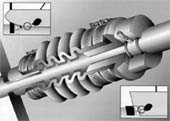

It seems my packing has met the end of its usefullness as no matter how much I mess around with the adjustment it still leaks a few drips per minute while sitting at the dock. If under power it drips quite a bit more. It seems that there is no way to change the packing easily as the packing gland nut will not back off enough to insert the new packing. On a boat with the Atomic engine the coupling to the engine is right behind the packing nut. I was wondering if anyone has found a way to change the packing while in the water. Is it possible to drop the shaft and do it that way? If I do drop the shaft will water rush in at all? I would secure it with a clamp so it could not fall out if that is even possible as I would think it would contact the rudder first. Another concern is the 4 bolts on the rear of the engine where I assume i disconnect look quite corroded up from sea water.....so I am a bit concerned about snapping a bolt, any comments concerns?????

thanks alll

It seems my packing has met the end of its usefullness as no matter how much I mess around with the adjustment it still leaks a few drips per minute while sitting at the dock. If under power it drips quite a bit more. It seems that there is no way to change the packing easily as the packing gland nut will not back off enough to insert the new packing. On a boat with the Atomic engine the coupling to the engine is right behind the packing nut. I was wondering if anyone has found a way to change the packing while in the water. Is it possible to drop the shaft and do it that way? If I do drop the shaft will water rush in at all? I would secure it with a clamp so it could not fall out if that is even possible as I would think it would contact the rudder first. Another concern is the 4 bolts on the rear of the engine where I assume i disconnect look quite corroded up from sea water.....so I am a bit concerned about snapping a bolt, any comments concerns?????

thanks alll