We have a 1985 E32-3. Cabin sole is badly rotted around mast step. Entire sole looks pretty ratty. I'm considering ripping out and starting over.

As I start planning this project, I have some questions:

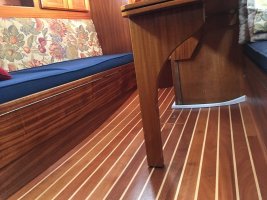

1. Does anyone know the construction of the sole in a 1985 boat? I have the impression that the teak holly is only 1/4" thick and that it is installed over a sub-floor of other material (probably marine plywood). Is this correct, or is the teak holly the full thickness (about 3/4")?

2. Even if the original floor is a single layer of plywood, I might replace it with a thin (and cheaper) finish layer of 1/4" teak-holly over a non-finish structural sub-floor. The sub-floor could be marine plywood or possibly some kind of composite panel. The material would need to be strong enough to span between the "frames" of the structural grid without sagging. Does anyone know if a synthetic panel such as "starboard" would be suitable for a concealed structural sub-floor?

3. Treating the sole as a finish applied over a separate structural panel opens the option of using a fake "teak-holly" marine vinyl floor instead of expensive T.H. plywood. Vinyl floor sounds yucky, but I'd rather be sailing than refinishing a wood floor every spring, so it is tempting. Does anyone have experience with marine vinyl products such as "PlasTeak" flooring? If I installed a vinyl floor, would I risk excommunication from the Ericson community?

As I start planning this project, I have some questions:

1. Does anyone know the construction of the sole in a 1985 boat? I have the impression that the teak holly is only 1/4" thick and that it is installed over a sub-floor of other material (probably marine plywood). Is this correct, or is the teak holly the full thickness (about 3/4")?

2. Even if the original floor is a single layer of plywood, I might replace it with a thin (and cheaper) finish layer of 1/4" teak-holly over a non-finish structural sub-floor. The sub-floor could be marine plywood or possibly some kind of composite panel. The material would need to be strong enough to span between the "frames" of the structural grid without sagging. Does anyone know if a synthetic panel such as "starboard" would be suitable for a concealed structural sub-floor?

3. Treating the sole as a finish applied over a separate structural panel opens the option of using a fake "teak-holly" marine vinyl floor instead of expensive T.H. plywood. Vinyl floor sounds yucky, but I'd rather be sailing than refinishing a wood floor every spring, so it is tempting. Does anyone have experience with marine vinyl products such as "PlasTeak" flooring? If I installed a vinyl floor, would I risk excommunication from the Ericson community?