It's a 6-pack (for $8.99) ;-)I looked at your link, but the price stated is $8.99.

I paid about that or a bit less for some similar bulbs from Fisheries in Seattle.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Beginning a refit of E32-3 - what to tackle first?

- Thread starter nquigley

- Start date

It's a 6-pack (for $8.99) ;-)

Ah So! At that price any bad ones can be tossed out without remorse.

32-3 rigging tension measurements

I'm starting the process of replacing all standing rigging this weekend - I'm going to do it bit-by-bit to spread the eye-watering cost out over about 6 months.

First, I want to measure my current stay and shroud tensions so I can use those values as a starting point when re-tuning with new wires.

I have a Loos gauge that's calibrated to measure all the wire sizes except the forestay.

But, if I take an 'uncalibrated' measurement of the forestay, I'll at least have some sort of value to get back to later using the same gauge.

Does anyone here have actual E32 rig tension measurements as a reference for me?

Or, do non-racing people generally just aim to be within the recommended %-of-breaking-strength value range, and just make opposing stays equal tension?

Hayn offers this info:

http://www.hayn.com/tech/wire_breaking_strength.html

- They say not to exceed 40% of breaking strength, but I recall reading on-line somewhere that cruisers should be in the ~10-15% range

- any thoughts?

Thanks!

I'm starting the process of replacing all standing rigging this weekend - I'm going to do it bit-by-bit to spread the eye-watering cost out over about 6 months.

First, I want to measure my current stay and shroud tensions so I can use those values as a starting point when re-tuning with new wires.

I have a Loos gauge that's calibrated to measure all the wire sizes except the forestay.

But, if I take an 'uncalibrated' measurement of the forestay, I'll at least have some sort of value to get back to later using the same gauge.

Does anyone here have actual E32 rig tension measurements as a reference for me?

Or, do non-racing people generally just aim to be within the recommended %-of-breaking-strength value range, and just make opposing stays equal tension?

Hayn offers this info:

http://www.hayn.com/tech/wire_breaking_strength.html

- They say not to exceed 40% of breaking strength, but I recall reading on-line somewhere that cruisers should be in the ~10-15% range

- any thoughts?

Thanks!

Last edited:

I would work with a professional rigger on this. Advice, discounts, and you can still do as much yourself as comfortable with.

Everything needs to be inspected and reviewed, including chainplates, toggles, turnbuckles, mast rake and so on.

"Weakest link in the chain" etc.

Everything needs to be inspected and reviewed, including chainplates, toggles, turnbuckles, mast rake and so on.

"Weakest link in the chain" etc.

Last edited:

I definitely would like to, but the nearest rigging shop is a 7-hour drive from here (Charleston, SC).I would work with a professional rigger on this. Advice, discounts, and you can still do as much yourself as comfortable with.

Everything needs to be inspected and reviewed, including chainplates, toggles, turnbuckles, mast rake and so on.

"Weakest link in the chain" etc.

The nearest TravelLift or mast crane is 8 hours down the river (there's one about an hour away, but his approach is only deep enough for powerboats).

There are only a few boats at our club with taller masts than mine, so lifting mine out using a taller mast on each side is a bit of a challenge to set up.

I plan to send one pair of stays at a time to WM's rigging shop in SC (free shipping via the local WM retail store). Plus, WM, under it's new ownership, is aggressively price-matching, so I'm confident I'll get OK pricing through them. Forestay and backstay will obviously be sent away in separate shipments.

I can inspect chainplates and deck rings, and I'll be replacing all turnbuckles, toggles. etc.

I think I can inspect the bearing points of the t-ball slots in the mast looking for cracks and corrosion.

I'm quite practiced at climbing my mast - I have a safe, efficient and comfortable system that doesn't need/use anyone else to help - so that's not a challenge. A few weeks ago, I was up there comfortably for two hours installing a pair of folding mast steps for convenient access to mast head fittings/equipment, and doing some other checks and maintenance.

I've tuned a few rigs before, so I'm sure I can get the rake and other key settings right.

Sounds like you know more about this stuff than I do.

Not everybody realizes the turnbuckles need to be changed too, and chainplates--including the bow stem fabrication--need a hard look.

My own inspections have flunked several times, so just don;t be me.

Here's one I missed from a bosun's chair, but a rigger found. The crack was inside, and not very apparent.

New rigging is a great comfort, and every owner for the next 20 years will sing your praises.

Not everybody realizes the turnbuckles need to be changed too, and chainplates--including the bow stem fabrication--need a hard look.

My own inspections have flunked several times, so just don;t be me.

Here's one I missed from a bosun's chair, but a rigger found. The crack was inside, and not very apparent.

New rigging is a great comfort, and every owner for the next 20 years will sing your praises.

Attachments

Sounds like you know more about this stuff than I do.

Not everybody realizes the turnbuckles need to be changed too, and chainplates--including the bow stem fabrication--need a hard look.

My own inspections have flunked several times, so just don't be me.

Here's one I missed from a bosun's chair, but a rigger found. The crack was inside, and not very apparent.

New rigging is a great comfort, and every owner for the next 20 years will sing your praises.

Thanks! Yes, I saw that horrifying t-ball pic on another thread - there's no way one could see that from a bosun's chair :-\

Knowing a bit about the history of my boat, I suspect that my standing rigging may be OEM - 33 years old! The WM rigger said he'd thoroughly inspect the old rigging as it comes in, just for interest sake - there'll be no discussion about possibly re-using any bits - I want that feeling of comfort you mentioned. In that context, I appreciated your earlier comment about pros and cons of owner-installed compression connectors like STA-LOK - that a future inspector, or insurance company, may baulk at a DIY job. That helped me decide to get WM to make new swaged stays throughout.

WM to make new swaged stays throughout.

What T-lock swage fittings is West going to use? Hayn, or....?

The rigger (Donny) recommended Hayn. He said that the original T-ball end fittings that the spar maker (Kenyon) used may not be available, but Hayn have an equivalent one that mates with the bearing plate that the original ones were designed for. He also said they may offer a lollypop-shaped end fitting that fits in the slot and mates properly to the bearing plate. The lollipop design is apparently much less prone to the stress-crack you found in the hooked t-ball design.What T-lock swage fittings is West going to use? Hayn, or....?

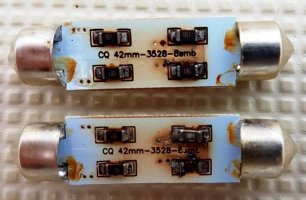

Beware that some of the cheap LED bulbs sold on Amazon overheat and eventually destroy themselves. Especially during charging the batteries when voltage is higher. Yours seem to have built-in heatsink so you may be OK. Just keep an eye on them. I just replaced a bunch of ~$1 LED bulbs with a much better stuff from Marinebeam. Old bulbs would flicker on/off and upon inspection I saw solder joints failing and PCBs discolored from overheating. IMHO fire hazard. Key words to look for in a better quality bulbs are "constant current" or "wide voltage range".This weekend, I replaced all incandescent bulbs with LED ones in the domed cabin lamps.

I used these bulbs:

https://www.amazon.com/gp/product/B00LMZZNU4/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1

About $1.50 each.

Cheap LED bulbs will only work in one orientation because they are nothing more than a string of LEDs and a ballast resistor. BTW, about half of the power goes into heating that ballast resistor.Interesting - they only work in one orientation (polarity sensitive).

Very helpful advice - I'll keep an eye on them - I did notice that the first ones I tried (which were a little too short) got quite hot - they can't be saving much electricity (compared to incandescent) if they are giving off so much heat - you get what you pay for, as always.Beware that some of the cheap LED bulbs sold on Amazon overheat and eventually destroy themselves. Especially during charging the batteries when voltage is higher. Yours seem to have built-in heatsink so you may be OK. Just keep an eye on them. I just replaced a bunch of ~$1 LED bulbs with a much better stuff from Marinebeam. Old bulbs would flicker on/off and upon inspection I saw solder joints failing and PCBs discolored from overheating. IMHO fire hazard. Key words to look for in a better quality bulbs are "constant current" or "wide voltage range".

Cheap LED bulbs will only work in one orientation because they are nothing more than a string of LEDs and a ballast resistor. BTW, about half of the power goes into heating that ballast resistor.

The local West Marine store manager (whom I trust very much) recommended I go for cheap (Amazon) LEDs for the cabin lights, but to get 'marine' LEDs for on-deck/mast running lights.

The WM bulbs were a shocking price ($59 each) .. until the store manager did their new price-match guarantee, searched the P/N on-line for me in the store and sold them to me for $9.90 each !!

Here is a pic of cheap LED bulbs removed after 2 years of service. Overheating caused PCB discoloration, solder joint failure and one of the ballast resistors even fell off.Very helpful advice - I'll keep an eye on them - I did notice that the first ones I tried (which were a little too short) got quite hot - they can't be saving much electricity (compared to incandescent) if they are giving off so much heat - you get what you pay for, as always.

As for comparison to the incandescent bulbs, even these were giving 5-6 times lower power consumption. Better LED bulbs can improve this number by about another 1.5-2x since cheap bulbs are wasting "only" half of the power.

For example FS-42-06 bulbs from Marinebeam are speced at 0.082A whereas "Amazon" bulbs were taking about 0.15A.

Well, to compare apples to apples we really should be looking at lumen/W numbers but good luck finding these.

$9.90 is more like it. I have a pretty good idea of what goes into a good LED bulb and it ain't $59 worth of stuff, even after West Marine markup. Marinebeam was more inline with $10 price range. Even that is too high but then again it has word "Marine" in it ;-)The local West Marine store manager (whom I trust very much) recommended I go for cheap (Amazon) LEDs for the cabin lights, but to get 'marine' LEDs for on-deck/mast running lights.

The WM bulbs were a shocking price ($59 each) .. until the store manager did their new price-match guarantee, searched the P/N on-line for me in the store and sold them to me for $9.90 each !!