I want to add 1" track for a jib car forward for a better head sail shape. The current track is to far aft. I pulled off the interior panels to look at how they are fastened, but it appears that there is no access to the bottom of the toe rails any through bolts? Has anyone ever added track to the toe rail of an E27?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Adding Track to the Toe Rail of my E27

- Thread starter G Kiba

- Start date

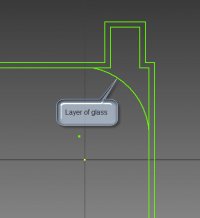

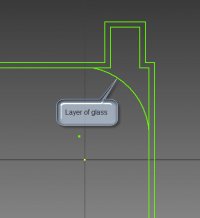

My 29 has a layer of cloth across the bottom of the toe-rail, although it is spotty or missing directly under the genoa track. So there is kinda sorta some access, though the nuts appear to be embedded in the resin anyway. Apparently they didn't do all boats the same. It's gonna be a nasty job to replace them, some day. (One is loose, and there is no way to get any purchase on it.) I should think that you could drill all the way through, keeping the drill very straight, with all the usual caveats of making holes in the deck. There might be some other material stuffed up inside the shape of the toe-rail too.

Oh, and there might be wires for the nav lights up in there too - the original ones were embedded in the fiberglass.

Oh, and there might be wires for the nav lights up in there too - the original ones were embedded in the fiberglass.

Last edited:

Thanks Todd,

They did a great job of glassing over mine. All I see is just a nice clean radius. I'll try drilling through the first track hole to see where it comes out.

Is this about what they did on your boat? Do you think I can drill the interior hole large enough to get a washer and nut on a through bolt that holds down the track?

They did a great job of glassing over mine. All I see is just a nice clean radius. I'll try drilling through the first track hole to see where it comes out.

Is this about what they did on your boat? Do you think I can drill the interior hole large enough to get a washer and nut on a through bolt that holds down the track?

You might need an exploratory hole to see what's going on. I think mine has some wads of mat, that were soaked in resin and stuffed up into the hollow, then glassed over. But I don't know if it's continuous all the way around.

If it is hollow, I would consider filling it with solid backing and bringing the nut and washer out into the accessible area. Basically, I feel that the way mine is built, the toe-rail is not strong enough. The reason is that my toe-rail was actually cracked open at some point in the past, by some kind of force on the genoa track. (Maybe a mooring line tied around the track or maybe a collision? I can't figure out how they did that.) I made a half-vast repair, sealed with 5200 and basically forgot about it. But Some Day it will have to be Dealt With.

Found a pic from my initial survey. This damage was the main reservation that I had about buying the boat in the first place.

If it is hollow, I would consider filling it with solid backing and bringing the nut and washer out into the accessible area. Basically, I feel that the way mine is built, the toe-rail is not strong enough. The reason is that my toe-rail was actually cracked open at some point in the past, by some kind of force on the genoa track. (Maybe a mooring line tied around the track or maybe a collision? I can't figure out how they did that.) I made a half-vast repair, sealed with 5200 and basically forgot about it. But Some Day it will have to be Dealt With.

Found a pic from my initial survey. This damage was the main reservation that I had about buying the boat in the first place.

Last edited:

Toe Rail track

I'm not sure if this will help or not, but at one point this summer, the marina moved my boat, and left it tied up too tight on the movable mid-ship cleat that slid on the toe rail track. The tide went out, and pop! The cleat ripped out about 4' of toe rail track before someone cut the line. The point of this is:

It looked like there were nuts fiberglassed into the toe rail track, and the 1" machine screws were secured by these captive nuts. When the force was upward, it pulled the nuts straight out of the fiberglass. Usually the load is more lateral, I guess. But there wasn't any indication that it was ever through-bolted, as the nuts were fairly close to the surface.

The marina repaired the track, but I think I may re-do it better after projects #24-78 are complete.

If I was going to reverse engineer my track, I would say:

Mark the track holes on the toe rail.

Drill a 1" deep hole with a large enough diameter to fit a nut down at the bottom.

Put in the nut, and coat a machine screw with mold release wax install the screw in the nut with the head just below track level.

Fill the hole with thickened epoxy, and allow to cure.

Remove screw, and screw down track.

You may be able to put the nut in deeper, but mine has 1" machine screws, so I think that's how my toe rail track was constructed. Good Luck! And please post photos if you do it.

-Dean

E-32

I'm not sure if this will help or not, but at one point this summer, the marina moved my boat, and left it tied up too tight on the movable mid-ship cleat that slid on the toe rail track. The tide went out, and pop! The cleat ripped out about 4' of toe rail track before someone cut the line. The point of this is:

It looked like there were nuts fiberglassed into the toe rail track, and the 1" machine screws were secured by these captive nuts. When the force was upward, it pulled the nuts straight out of the fiberglass. Usually the load is more lateral, I guess. But there wasn't any indication that it was ever through-bolted, as the nuts were fairly close to the surface.

The marina repaired the track, but I think I may re-do it better after projects #24-78 are complete.

If I was going to reverse engineer my track, I would say:

Mark the track holes on the toe rail.

Drill a 1" deep hole with a large enough diameter to fit a nut down at the bottom.

Put in the nut, and coat a machine screw with mold release wax install the screw in the nut with the head just below track level.

Fill the hole with thickened epoxy, and allow to cure.

Remove screw, and screw down track.

You may be able to put the nut in deeper, but mine has 1" machine screws, so I think that's how my toe rail track was constructed. Good Luck! And please post photos if you do it.

-Dean

E-32

Thanks Dean and Todd for your thoughts on this toes rail stuff!

Todd, sorry to see the damage. It does look a bit weak in the cross-section. I suspect that the section was mean to resist forces up and down and not so much horizontal. Point of failure looks to be horizontal along the top of the toe rail.

Dean, any idea how the marina fixed your damaged toe rail? Was the toe rail hollow inside with an inner floor that could fill with epoxy?

I had the same thoughts about epoxying in some nuts but was not sure if the rail was solid enough. It would be great to have a backing washer. There is a lot of upward force on these screws.

Bruce King must have been thinking - glass-in the lead keel, the chain plates, heck why not the toe rail fasteners. Oh well - it's lasted over 40 years. Hard to argue if he was right or wrong. It's still a great design in my opinion.

Todd, sorry to see the damage. It does look a bit weak in the cross-section. I suspect that the section was mean to resist forces up and down and not so much horizontal. Point of failure looks to be horizontal along the top of the toe rail.

Dean, any idea how the marina fixed your damaged toe rail? Was the toe rail hollow inside with an inner floor that could fill with epoxy?

I had the same thoughts about epoxying in some nuts but was not sure if the rail was solid enough. It would be great to have a backing washer. There is a lot of upward force on these screws.

Bruce King must have been thinking - glass-in the lead keel, the chain plates, heck why not the toe rail fasteners. Oh well - it's lasted over 40 years. Hard to argue if he was right or wrong. It's still a great design in my opinion.

Hi Grant,

You might want to add an inner jib track on the side decks. This will give you a better sheeting angle for a smaller headsail and installation is easier. I did this on my 1976 E27 and use them with a 110% headsail. I looked for a photo but can't find one - I'll try to remember to take some photos when I'm at the boat.

You might want to add an inner jib track on the side decks. This will give you a better sheeting angle for a smaller headsail and installation is easier. I did this on my 1976 E27 and use them with a 110% headsail. I looked for a photo but can't find one - I'll try to remember to take some photos when I'm at the boat.

Marina repair

I think they may have epoxied a couple of the nuts back in place and secured the track back down, but I suspect they skipped a few and made up the difference with an entire tube of silicone because there's that much under the track now. The track used to have a good number of fasteners, Maybe one every 6" or so and now there are less. They didn't charge me for the 7 months I was in a slip, so I didn't complain too much. It doesn't leak, and I don't use that section normally, so I can work on it at my leisure.

I like the idea of an inner track as well. I think it will become project #87.

Dean

I think they may have epoxied a couple of the nuts back in place and secured the track back down, but I suspect they skipped a few and made up the difference with an entire tube of silicone because there's that much under the track now. The track used to have a good number of fasteners, Maybe one every 6" or so and now there are less. They didn't charge me for the 7 months I was in a slip, so I didn't complain too much. It doesn't leak, and I don't use that section normally, so I can work on it at my leisure.

I like the idea of an inner track as well. I think it will become project #87.

Dean

Mark,

I have an inner track that I added. Works well for my 80% and ok for the 95%. I feel I could get a little better performance with an outer track for the 95% or larger in this case. Both my sails are deck sweeping. The 95% sheets between the forward and upper shroud and the sail can be on the inside or outside the lifelines. Just feel I can close the slot with an outside track. However, may not be worth the effort. Could probably get a higher cut clue and use the rear tracks id I went to a 115-120%. Funny thing is that I use the 80% more often in the spring and summer than the 95. Thanks all. Happy waiting for spring.

I have an inner track that I added. Works well for my 80% and ok for the 95%. I feel I could get a little better performance with an outer track for the 95% or larger in this case. Both my sails are deck sweeping. The 95% sheets between the forward and upper shroud and the sail can be on the inside or outside the lifelines. Just feel I can close the slot with an outside track. However, may not be worth the effort. Could probably get a higher cut clue and use the rear tracks id I went to a 115-120%. Funny thing is that I use the 80% more often in the spring and summer than the 95. Thanks all. Happy waiting for spring.

outside track

Greg,

No doubt these boats could stand having a bit more track farther forward -especially for use with smaller LP sails and even more especially when reaching.

If as you say you have low cut clews on your smaller headsails then you are right-you may not be able to get the car far enough forward for proper sail trim, and the more eased the sheets are the more pronounced this will be.

As Mark said, the inside tracks should be more effective when sailing close hauled with smaller sails, and the outboard tracks will improve performance when reaching, or maybe beating into very large seas and heavy air when a more open slot is helpful.

BUT- do not make the mistake of adding tracks to accomdate sails which are not really designed for the boat. Much better to recut or have a new sail built which will be designed to sheet where you want it and/or have track.-Also not sure what you mean by "closing the slot". Especially with heavy air sails, this is not something you really want to do, and BTW-outboard tracks will open the slot compared to inboard tracks

Happy New Year

S

Greg,

No doubt these boats could stand having a bit more track farther forward -especially for use with smaller LP sails and even more especially when reaching.

If as you say you have low cut clews on your smaller headsails then you are right-you may not be able to get the car far enough forward for proper sail trim, and the more eased the sheets are the more pronounced this will be.

As Mark said, the inside tracks should be more effective when sailing close hauled with smaller sails, and the outboard tracks will improve performance when reaching, or maybe beating into very large seas and heavy air when a more open slot is helpful.

BUT- do not make the mistake of adding tracks to accomdate sails which are not really designed for the boat. Much better to recut or have a new sail built which will be designed to sheet where you want it and/or have track.-Also not sure what you mean by "closing the slot". Especially with heavy air sails, this is not something you really want to do, and BTW-outboard tracks will open the slot compared to inboard tracks

Happy New Year

S

Last edited: