My 72 e29 toe rail has a bunch of cracks in it. At some points it’s seperating where the cracks are. I’m not quite sure the best way to repair it, because there doesn’t seem to be enough room to scarf in more fiberglass at a 12:1 ratio due to the deck/hull joint. Any ideas?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

E29 Toe Rail Repair

- Thread starter ooo000ooo

- Start date

Are you sure it's not just cracks in the gel coat? My understanding is that the acute angle and thick buildup of gelcoat in the mold makes that part prone to gel coat cracking. Anyway mine sure has a lot of them. Which I'm about to start grinding on if the weather holds.

I also do have a real crack in the toe rail from some long-ago impact. When I first bought the boat, I slathered it over inside and out with 5200 and forgot about it for the next seven years. But now it's time to get real about it.

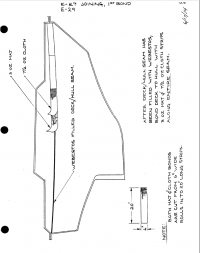

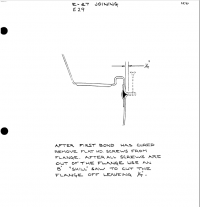

So, the toe rail is an inverted U shape that's part of the deck. You can access it from inside the "ducts." Except in some places it's open and in others, the open side has been glassed over. Or just (apparently) some resin-saturated matting was stuffed into it. (This cleverly prevents access to the genoa track bolts.)

Let's see if I can find some pics from my original survey.

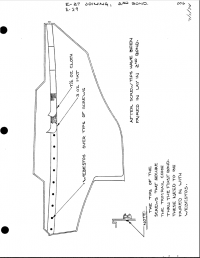

Actual toe-rail crack:

The developing plan is to use a can opener or dremel tool to open up the gel coat cracks and chips, then fill with thickened epoxy as per the West systems manual. For the crack, i think the best course may be to patch it from the inside. Building up any more material on the outside would interfere with the genoa track. One idea I'm toying with is to shape a wedge of hardwood about three times as long as the crack to fill the "U" and epoxy it into place. Then drill all the way through it for new genoa track fasteners. Ah - note the adjacent scupper which... scuppers that plan. But something like that.

When all the various booboos on the deck are fixed, I'll paint the whole thing with a two-part polyurethane. Probably next March or so.

I also do have a real crack in the toe rail from some long-ago impact. When I first bought the boat, I slathered it over inside and out with 5200 and forgot about it for the next seven years. But now it's time to get real about it.

So, the toe rail is an inverted U shape that's part of the deck. You can access it from inside the "ducts." Except in some places it's open and in others, the open side has been glassed over. Or just (apparently) some resin-saturated matting was stuffed into it. (This cleverly prevents access to the genoa track bolts.)

Let's see if I can find some pics from my original survey.

Actual toe-rail crack:

The developing plan is to use a can opener or dremel tool to open up the gel coat cracks and chips, then fill with thickened epoxy as per the West systems manual. For the crack, i think the best course may be to patch it from the inside. Building up any more material on the outside would interfere with the genoa track. One idea I'm toying with is to shape a wedge of hardwood about three times as long as the crack to fill the "U" and epoxy it into place. Then drill all the way through it for new genoa track fasteners. Ah - note the adjacent scupper which... scuppers that plan. But something like that.

When all the various booboos on the deck are fixed, I'll paint the whole thing with a two-part polyurethane. Probably next March or so.

Are you sure it's not just cracks in the gel coat? My understanding is that the acute angle and thick buildup of gelcoat in the mold makes that part prone to gel coat cracking. Anyway mine sure has a lot of them. Which I'm about to start grinding on if the weather holds.

I also do have a real crack in the toe rail from some long-ago impact. When I first bought the boat, I slathered it over inside and out with 5200 and forgot about it for the next seven years. But now it's time to get real about it.

So, the toe rail is an inverted U shape that's part of the deck. You can access it from inside the "ducts." Except in some places it's open and in others, the open side has been glassed over. Or just (apparently) some resin-saturated matting was stuffed into it. (This cleverly prevents access to the genoa track bolts.)

Let's see if I can find some pics from my original survey.

Actual toe-rail crack:

View attachment 25411

The developing plan is to use a can opener or dremel tool to open up the gel coat cracks and chips, then fill with thickened epoxy as per the West systems manual. For the crack, i think the best course may be to patch it from the inside. Building up any more material on the outside would interfere with the genoa track. One idea I'm toying with is to shape a wedge of hardwood about three times as long as the crack to fill the "U" and epoxy it into place. Then drill all the way through it for new genoa track fasteners. Ah - note the adjacent scupper which... scuppers that plan. But something like that.

When all the various booboos on the deck are fixed, I'll paint the whole thing with a two-part polyurethane. Probably next March or so.

It's definitely past cracks in the gel coat in some of the places. There's moss growing inside some of them :0. It looks like the previous owner filled them with.. something like 5200 as well (and replaced some of the stantion bases with pieces of wood???? but that's another topic). But fixing it from the inside is a good idea, as big of a pain as that will be. Sounds like I have a lot of grinding in my future just to even remove the genoa track. And the hardwood idea sounds like it may work as well. It would add the structural integrity without having to scarf in the fiberglass as much (which is basically impossible anyways). I also want to paint it with a two part polyurethane once all stuff is fixed. Definitely some good ideas though thank you! I have a fun winter ahead of me. And here is some pictures of how bad mine is (it looks much worse in person):

Interesting. I had been assuming that this was impact damage. I suppose it’s possible that it’s just a weak point on these boats. I’ve been developing a theory that the boat was laid over on its port side at some point. When I stripped all the paint off the bottom, I found a football-shaped area on the waterline with a lot of gel coat cracking just below that toe-rail crack. And recently I discovered a crack in the liner flange that holds the main bulkhead on that side.

Interesting. I had been assuming that this was impact damage. I suppose it’s possible that it’s just a weak point on these boats. I’ve been developing a theory that the boat was laid over on its port side at some point. When I stripped all the paint off the bottom, I found a football-shaped area on the waterline with a lot of gel coat cracking just below that toe-rail crack. And recently I discovered a crack in the liner flange that holds the main bulkhead on that side.

It could be a little bit of both. I plan on stripping the bottom paint off as well, so we will see. I also have a crack on the flange that holds the bulkhead. There is one in identical places on both port and starboard. The previous owner filled it with what appears to be just gelcoat, but it doesn't look like it cracked any more since it was filled. I'm assuming that was due to some sort of impact as well. So I guess if we both have those issues it must be a weak point.

When a hull takes a strong impact or force against one side, it can also cause real damage on the opposite side.

If you recall the incident from a few summers ago when a whale leaped straight up and came down on the starboard deck of 35 foot sailboat, just off the mouth of the Columbia, that was a guy from our YC.

The starboard side hull/deck joint was obviously damaged, but there was significant damage on the other side where the boat had momentarily flexed and had the interior bulkhead pushed across very hard, and the port side joint was also damaged.

Fixable, but insurance totaled it. The hull and deck joint would have to be rebuilt on both sides, and the bulkhead likely needed work too.

I looked at the outside of the port side, later, and there was very little external evidence.

That "collision" was a statistical anomaly, but any hard collision can have deeper effect on most any vessel.

If you recall the incident from a few summers ago when a whale leaped straight up and came down on the starboard deck of 35 foot sailboat, just off the mouth of the Columbia, that was a guy from our YC.

The starboard side hull/deck joint was obviously damaged, but there was significant damage on the other side where the boat had momentarily flexed and had the interior bulkhead pushed across very hard, and the port side joint was also damaged.

Fixable, but insurance totaled it. The hull and deck joint would have to be rebuilt on both sides, and the bulkhead likely needed work too.

I looked at the outside of the port side, later, and there was very little external evidence.

That "collision" was a statistical anomaly, but any hard collision can have deeper effect on most any vessel.

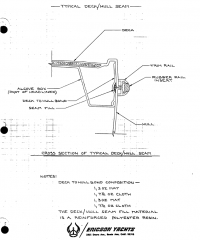

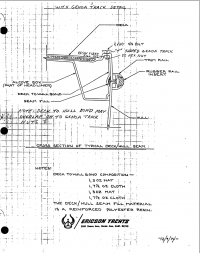

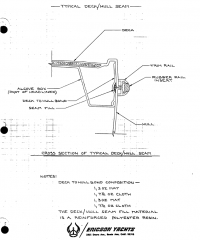

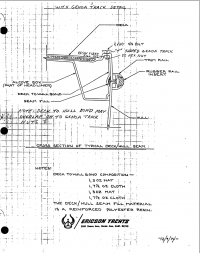

Someplace there is a series of "chainsaw cross-section" pics of an E29. This is the only one I can find - not sure if it's a 29.

From the shattered bit on my boat, it's obvious that the layup in my toe rail isn't nearly as thick as shown in the photo. Less than half that thick on the outside, I'd say. Looks like it could be a "weak link" between the hull and deck. Although as mentioned above, the gap is tabbed across in places. Maybe the whole thing should have been.

From the shattered bit on my boat, it's obvious that the layup in my toe rail isn't nearly as thick as shown in the photo. Less than half that thick on the outside, I'd say. Looks like it could be a "weak link" between the hull and deck. Although as mentioned above, the gap is tabbed across in places. Maybe the whole thing should have been.

Someplace there is a series of "chainsaw cross-section" pics of an E29. This is the only one I can find - not sure if it's a 29.

View attachment 25419

From the shattered bit on my boat, it's obvious that the layup in my toe rail isn't nearly as thick as shown in the photo. Less than half that thick on the outside, I'd say. Looks like it could be a "weak link" between the hull and deck. Although as mentioned above, the gap is tabbed across in places. Maybe the whole thing should have been.

I have heard that some other production sailboats have a glassed-together hull/deck joint.... but not very darned many. OTOH, pushing fibers into the toe rail part of the tooling was difficult no matter who was building the boat.

For instance O'Day used to build really sharp-edged tooling along the deck perimeter and cockpit, and this led to voids under the initial gel coat that broke out and revealed nasty little holes many years later.

It is even worse for hulls where someone had to stuff cloth and resin down into the narrow mold for a skeg rudder attachment.

Thanks for sharing the photo.

Upon further inspect it seems that there was a large repair area right on the bow, so that could done a lot of the damage, hard to say anyways.

Also I found the source of that cut up boat.. It's an e34

http://www.ericsonyachts.org/infoex...ck-Reinforcement&p=66035&viewfull=1#post66035

It looks like the area with the track is completely solid, whereas past the track is hollow.

Part of me says just screw it, put some more sealant on the cracks, and hope the track doesn't fly off (I mean it did survive some pretty good blows this year as is). I'll just have to do some more investigating I guess.

Also I found the source of that cut up boat.. It's an e34

http://www.ericsonyachts.org/infoex...ck-Reinforcement&p=66035&viewfull=1#post66035

It looks like the area with the track is completely solid, whereas past the track is hollow.

Part of me says just screw it, put some more sealant on the cracks, and hope the track doesn't fly off (I mean it did survive some pretty good blows this year as is). I'll just have to do some more investigating I guess.

Last edited:

Thanks, sometimes the google-fu is weak. If it's all solid inside, I'd be tempted to just glue & clamp it back together, maybe with a strip of reinforcement on the outside. The only alternative would seem to be to cut and grind away a lot of stuff and rebuild.

One could always drill an exploratory hole. A core sample might be instructive - IDK if a small coring bit would work on fiberglass. That is, I want to know if the interior is still solid or if it's shattered or delaminated. I'll need to do some kind of drilling anyway, to get some of the track bolts free.

Is there any evidence that water ever came through the cracked area?

One could always drill an exploratory hole. A core sample might be instructive - IDK if a small coring bit would work on fiberglass. That is, I want to know if the interior is still solid or if it's shattered or delaminated. I'll need to do some kind of drilling anyway, to get some of the track bolts free.

Is there any evidence that water ever came through the cracked area?

Yeah, I'll just have to look from the inside/do a little exploratory cutting or drilling to see. I'll take a look this weekend. And there is definitely water coming in, I would assume from the toe rail cracks, but also from the very poorly repair stantion bases (on a couple of them the raised part was replaced with a piece of wood, and flexing over time probably made the sealant fail).

Yeah, the stanchion and pulpit bases were a bit problematic. Especially when "helpful" people pull on the stanchions. Inadequate backing and the raised bits on deck seem to have voids behind them. I've been using a large syringe to fill the voids with epoxy. Probably deck core issues all around.

Avoiding "point loading"

Stanchions can be braced on any boat, but the method of attachment will differ.

Making ours stronger was one of our best upgrades.

http://www.ericsonyachts.org/infoexchange/showthread.php?3371-Stanchion-Bracing&referrerid=28

Stanchions can be braced on any boat, but the method of attachment will differ.

Making ours stronger was one of our best upgrades.

http://www.ericsonyachts.org/infoexchange/showthread.php?3371-Stanchion-Bracing&referrerid=28

Good idea about bracing the stanchions. I finally got around to looking closer at the rail, and underneath it is completely glassed in until just about the first chain plate. I don't even see the ends of the screws for the track, not sure how I would even get that off. Also I found one part where it looks like all the fiberglass has worn away for some reason or another, and it looks completely solid inside. Just like that cut apart boat.

I wonder if that solid filler could be the mysterious "webestos," a substance whose nature has been lost in time. Except the construction notes in the Ericson manuals say that the hull-deck seam was filled with it before being glassed together. When I peered up into the void, I thought it was fiberglass mat. But I don't know. When I took the rub-rail off, there was nothing between the lips of the hull deck joint, so half of the rubrail screws had no grip, and I was thinking I should try to squeeze some 5200 into it or something.

It very well could be. Based on my research asbestos was used very commonly in boat building back then. In caulks, sealants, gaskets, as well as resin fillers. The color of what I can see in the tow rail is white, and so is asbestos powder, although so is fumed silica. I have also heard of the filler being green. Apparently asbestos filler added a lot of strength, so it would have made sense to use in this application. I only looked at the hull deck join from the inside but I didn't see any sort of filler or void. Maybe I didn't look close enough. I guess the only way to tell would be a lab test. Oh well either way it can't be much worse than it would be to breathe in the straight fiberglass dust from grinding it anyways. And apparently since it is mixed in the resin the asbestos is encapsulated and isn't really any more harmful than the resin dust itself. A tyvek suit and a respirator with a p100 filter should be do the trick.

Last edited:

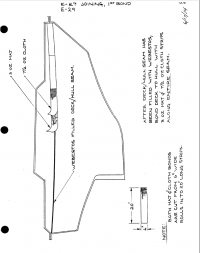

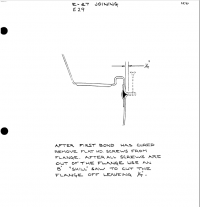

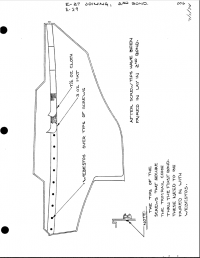

Also I just looked at the manual, and maybe they did it differently before this was written because my hull deck seam does not seem like how it is shown in the manual. I can see the screws coming inside the boat from the trim rail, even though the manual indicates that they should be hidden by this asbestos mixture that is glassed over. It just looks completely flat to me. And the last picture shows the construction of the toe rail and genoa track. It says it is "resin fibre fill mtl" which I am assuming means it is asbestos free. And it looks like the track is held onto this with a screw and nut, which I can't access because they completely glassed that area over. And apparently some of the screws are covered with the deck hull bond. So I really don't know how to remove that track without cutting out all the fiberglass beneath it which I really don't want to do. I guess the only option is to work around it.