I need to replace the sheaves on my '76 E27. I will also the be converting to all-rope halyards. I have already received a quote from Zephyrwerks.

I'd like to do the work with the mast still standing.

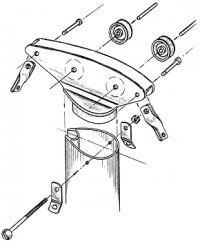

My plan is to climb the mast using a Top Climber and one of the halyards. Then drill a hole in the mast head itself, attach a large shackle and run a line back down to the mast base and use this line to climb back up. Then theoretically I can pull the axles, remove the old sheaves and install the new.

Is this possible? This is how the current topping lift is installed.

Thanks

I'd like to do the work with the mast still standing.

My plan is to climb the mast using a Top Climber and one of the halyards. Then drill a hole in the mast head itself, attach a large shackle and run a line back down to the mast base and use this line to climb back up. Then theoretically I can pull the axles, remove the old sheaves and install the new.

Is this possible? This is how the current topping lift is installed.

Thanks

Last edited: