I've had my compass removed for a little winter refurb--I refilled the fluid, installed an LED bulb, polished the bakelite case, and I'm refinishing the teak base it sits on. I went to test-fit the parts last night and, OH SH!%, I fumbled one of the 1/4 x 2" screws. It dropped, of course, right down the center of the steering pedestal. I heard it make a solid, metallic "clink" when it landed about 2' down near the base of the pedestal.

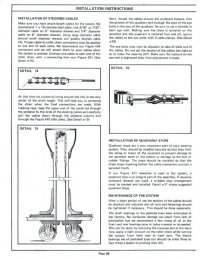

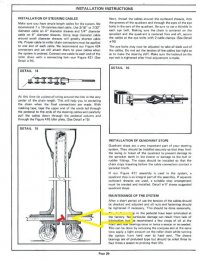

(borrowed photo, but similar setup--shows where I dropped the screw).

Short of disassembling the whole pedestal per Christian's excellent instructions above, anyone have a simpler idea for possibly retrieving the screw. A loose 2" bolt laying at the bottom of my steering chain assembly is probably beyond my comfort level for leaving as is.

Just when I though I was making headway wrapping up the winter projects.

(borrowed photo, but similar setup--shows where I dropped the screw).

Short of disassembling the whole pedestal per Christian's excellent instructions above, anyone have a simpler idea for possibly retrieving the screw. A loose 2" bolt laying at the bottom of my steering chain assembly is probably beyond my comfort level for leaving as is.

Just when I though I was making headway wrapping up the winter projects.

).

).