How can I improve access to my switch panel? It seems pretty constrained by the angled joinery at the nav station.

How much existing wiring will need to be or should be replaced?

Will we want an electric windlass vs manual that works well now?

Will we want a water maker?

Will we want Starlink at some point? The owner of the boat I just crewed on says in the real world his draws 8A when switched on and 3A when switched off (?!?)

How can I get the house bank amp hours we want (estimating 400 at this point) out of an AGM configuration? I’m not sold on lithium yet.

What’s the best way to spec a high performance alternator for our 30hp Yanmar that allows us to keep our existing alternator as a spare (OEM 125A Valeo that doesn’t get very good reviews for longevity)?

What kind of solar array will work best for us? Goal would be to stick with panels that can be mounted on existing dodger & bimini. We are too slow for hydro and don’t want a wind generator.

SoV,

I found BoatHowTo recently too, good call.

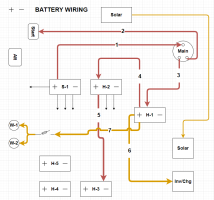

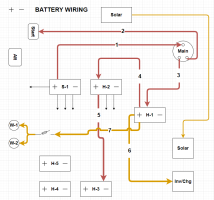

FWIW, I'm trying out diagrams.net for my wiring diagrams, free for mortals and works in any browser. Simple but competent (it, not me), so far.

This example was just trying to trace my battery wiring, doing a real plan should be a fun winter project:

I thought I heard there were EY stock diagrams around, but I haven't found them so far.

Regarding panel access, I don't know how the 38-200 is different from the 381 but if it's similar, I've now seen Christian's method of the fold down door done elsewhere and I'm convinced: better for the wires, better for working on them. It's basically a plywood cabinet face so basic cabinet skills should suffice, styled to match EY standards. I have a bit of wood butchery to address on mine so I have the 'advantage' of anything I do being an improvement to those areas.

I don't think I'll replace any wiring that doesn't test bad or look bad or is run/installed wrong. It's old but AFAIK, there's no expiration date.

I think the electric windlass decision should be based on how much you'll anchor out, whether or not you're single handing (using a remote), how much/heavy chain you expect to put out, the conditions you expect to find yourself in, and your physical condition. I kind of tick several of those, so if I didn't have one, I'd probably be looking for one, to help when conditions aren't optimal.

Regarding watermakers, I'm sure you'll get what you need but I saw a YT (I think it was on Emily and Clark's Adventure) about getting a used millitary model. Seemed clever.

Regarding batteries, mine came with 6 AGM-31M's (1 start, 5 house) @ 105AH ea, 3 in the quarter berth and 3 under the salon seat, I don't think I could fit any more in if I wanted (I don't). I see a lot of folks say you have to do a power budget, seems right. Clark, of Emily and Clark's Adventure is currently doing a lithium battery analysis and has some good, easy to understand input about them, as well as selling what seems like a well thought out battery bank manager that charges different batteries differently, as they need. I'm not qualified to say whether he's right but if I was going to buy all new, I'd definitely consider lithium for the house, AGM for starting, and one of his bank managers for protecting the investment.

For solar, mine came with 3 100W Renogy panels and looking into them, they seem to be a common choice. That said, solar seems to be a deep subject, compounded by the conditions of boating, so once you have your power budget, you'll have a better idea whether you can get by with basic stuff or need some of the higher end, higher producing gear (and perhaps flexible).

One thing I think is good advice I've heard, think a bit about what parts may be available where you are headed. Critical things like filters you want to be available everywhere. Optional things you could live without for a month while waiting for something to arrive through foreign customs, twice because of course the first one won't be the right one, those maybe don't matter so much.

Fun stuff.

.