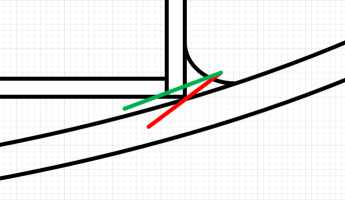

I'm planning to build a shelf under the port settee to mount my batteries. While I was cleaning the area I noticed the tabbing for the furniture does not have any limber holes to allow water to drain into the bilge. I don't have a lot of water getting in and accumulating here, but I do get a small amount after washing the boat or a wet sail to wind (pretty sure it's getting in through the portlights). Regardless of how it's getting in, I would like to ensure it has a way to get out before it damages the furniture. I was thinking of using a multitool to cut a slot in the tabbing at the low point. Has anyone run into this issue before? If so, what was your solution?