You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Installing your rudder.

Tim, I'm assuming that your new rudder will be foam filled correct? You might want to practice now before it comes by using a basketball in the bathtub. FIll it to capacity with water (a swimming pool is even better) then fully submerge the basketball and hold it on the bottom long enough for you to position yourself over it, it's that easy. Oh, did I mention that by positioned over it, I mean that you'll need to place both feet on it and stand in place on the basketball? And you can't touch the walls, that's cheating. Now if the rudder isn't buoyant, go for it but please do it in shallow water otherwise, if you lose your grip on her, she's gone forever. Hmmm, why not haul???? I too have removed and replaced my rudder........on the hard. Ciao, Glyn Judson, E31 hull #55, Marina del Rey, CA

Tim, I'm assuming that your new rudder will be foam filled correct? You might want to practice now before it comes by using a basketball in the bathtub. FIll it to capacity with water (a swimming pool is even better) then fully submerge the basketball and hold it on the bottom long enough for you to position yourself over it, it's that easy. Oh, did I mention that by positioned over it, I mean that you'll need to place both feet on it and stand in place on the basketball? And you can't touch the walls, that's cheating. Now if the rudder isn't buoyant, go for it but please do it in shallow water otherwise, if you lose your grip on her, she's gone forever. Hmmm, why not haul???? I too have removed and replaced my rudder........on the hard. Ciao, Glyn Judson, E31 hull #55, Marina del Rey, CA

tenders

Innocent Bystander

Are you sure all the holes are drilled in precisely the right places in the new rudderstock? How can you know this?

This is what a "short haul" is for. I have the simplest rudder installation possible -- a tiller -- and still had to finesse some of the clearances between the new rudder and the hull with a Dremel tool.

This is what a "short haul" is for. I have the simplest rudder installation possible -- a tiller -- and still had to finesse some of the clearances between the new rudder and the hull with a Dremel tool.

Short haul might be the answer.

Tim, I didn't know there was a word for it but short haul makes sense. My yard here in Marina del Rey, CA asks $75.00 to hang the boat on slings over the period of their lunch time, more than enough I'd think for what you want to do. Ask your yard is they offer such a service, that might be the best of all choices. Good luck, Glyn Judson, E31 hull #55, Marina del Rey, CA

Tim, I didn't know there was a word for it but short haul makes sense. My yard here in Marina del Rey, CA asks $75.00 to hang the boat on slings over the period of their lunch time, more than enough I'd think for what you want to do. Ask your yard is they offer such a service, that might be the best of all choices. Good luck, Glyn Judson, E31 hull #55, Marina del Rey, CA

A haul is best not doubt...

But here on the Great Salt Lake, a haul means bringing a crane in. We do not have haul out facilities. That's a price we pay for the solitude we enjoy when sailing her. That's a good chunk of coin even on designated crane days. The trick then would be to go first and get the rudder installed before the last boat pulls to avoid standby charges.

The rudder is foam and GSL floats well due to increased density, so its a challenge from that standpoint. No hole drilled until the post is positioned... No issue to do it though. Sounding like I'll have to haul or get very creative!

But here on the Great Salt Lake, a haul means bringing a crane in. We do not have haul out facilities. That's a price we pay for the solitude we enjoy when sailing her. That's a good chunk of coin even on designated crane days. The trick then would be to go first and get the rudder installed before the last boat pulls to avoid standby charges.

The rudder is foam and GSL floats well due to increased density, so its a challenge from that standpoint. No hole drilled until the post is positioned... No issue to do it though. Sounding like I'll have to haul or get very creative!

EGregerson

Member III

gsl

Has the yacht club hauled out for the season already? if so & u can't wait til spring; maybe run her aground in some soft place off Antelope Is; kedge her over; swap rudders; then call the DNR for a tow off (since there's no tide).

go Utes!

Has the yacht club hauled out for the season already? if so & u can't wait til spring; maybe run her aground in some soft place off Antelope Is; kedge her over; swap rudders; then call the DNR for a tow off (since there's no tide).

go Utes!

Gsl

The kedging idea is a consideration, but I hate to impose on the State again - . Pics are of Rescue One bringing her in with the busted rudder. I was 4 miles off Stansbury Isl. when I grounded on a Tufa Reef. They did an outstanding job of getting us in unscathed. We enjoy great support on the water and in the harbor from all the folks there. Water is 8 feet below normal pool right now. Sailing is getting depressing around here with the Marina mouth only 4.5 feet deep

. Pics are of Rescue One bringing her in with the busted rudder. I was 4 miles off Stansbury Isl. when I grounded on a Tufa Reef. They did an outstanding job of getting us in unscathed. We enjoy great support on the water and in the harbor from all the folks there. Water is 8 feet below normal pool right now. Sailing is getting depressing around here with the Marina mouth only 4.5 feet deep  .

.

GSL Yacht Club pulls on Nov 5. I am going to give it a shot with a pole system some folks at the marina have used in the past. If it doesn't work, its haul on the 5th and part with the coin. We sail here all winter, so I want to get her back underway. The rudder floats, so I've little to loose other than a few degrees of body heat and some pride . EGregerson...Go Utes???? You mean Go HOKIES!... I am a transplant from Virginia

. EGregerson...Go Utes???? You mean Go HOKIES!... I am a transplant from Virginia !

!

The kedging idea is a consideration, but I hate to impose on the State again -

. Pics are of Rescue One bringing her in with the busted rudder. I was 4 miles off Stansbury Isl. when I grounded on a Tufa Reef. They did an outstanding job of getting us in unscathed. We enjoy great support on the water and in the harbor from all the folks there. Water is 8 feet below normal pool right now. Sailing is getting depressing around here with the Marina mouth only 4.5 feet deep

. Pics are of Rescue One bringing her in with the busted rudder. I was 4 miles off Stansbury Isl. when I grounded on a Tufa Reef. They did an outstanding job of getting us in unscathed. We enjoy great support on the water and in the harbor from all the folks there. Water is 8 feet below normal pool right now. Sailing is getting depressing around here with the Marina mouth only 4.5 feet deep  .

.GSL Yacht Club pulls on Nov 5. I am going to give it a shot with a pole system some folks at the marina have used in the past. If it doesn't work, its haul on the 5th and part with the coin. We sail here all winter, so I want to get her back underway. The rudder floats, so I've little to loose other than a few degrees of body heat and some pride

Attachments

Rudder Install follow-up

In case someone finds this thread in the future, I wanted to complete the thread with the final results. After receiving the replacement rudder from Foss, I remained determined to install it without a haul. A haul in my neck of the woods means bringing in a crane... $$$.

As described by Glyn above, trying to install it was much like standing on a basket ball. I tried it, in 53 degree water, with the only success being some humiliation and learning how fast 53 degree water can suck the wind out of you. 10 mins later and I retreated to warmer quarters.

Not to be deterred, I constructed an "L" shaped pole with two 2X4s, installed a pulley on the lower horizontal section and tied a bridle on the rudder. The real trick was getting the bridle adjusted so that the rudder would stay vertical when submerged. Once done, I lashed the pole to the transom, turned the L under the boat, and submerged the rudder with the pulley and rope setup. I let the rudder post have sufficient scope to be about two inches higher than the bottom of the post sleeve. Then it was time for a cold swim again. Guided the post to the sleeve, started it, then eased the line to allow the rudder post to float up into the sleeve. A couple of twists and releasing of the bridle let the rudder rise into place...

Hauling would definately be the best gig. I was lucky that the fit was excellent and the shims well chosen to start. But in a pinch, either by time, distance, or cash... the pole and bridle could work for you...

In case someone finds this thread in the future, I wanted to complete the thread with the final results. After receiving the replacement rudder from Foss, I remained determined to install it without a haul. A haul in my neck of the woods means bringing in a crane... $$$.

As described by Glyn above, trying to install it was much like standing on a basket ball. I tried it, in 53 degree water, with the only success being some humiliation and learning how fast 53 degree water can suck the wind out of you. 10 mins later and I retreated to warmer quarters.

Not to be deterred, I constructed an "L" shaped pole with two 2X4s, installed a pulley on the lower horizontal section and tied a bridle on the rudder. The real trick was getting the bridle adjusted so that the rudder would stay vertical when submerged. Once done, I lashed the pole to the transom, turned the L under the boat, and submerged the rudder with the pulley and rope setup. I let the rudder post have sufficient scope to be about two inches higher than the bottom of the post sleeve. Then it was time for a cold swim again. Guided the post to the sleeve, started it, then eased the line to allow the rudder post to float up into the sleeve. A couple of twists and releasing of the bridle let the rudder rise into place...

Hauling would definately be the best gig. I was lucky that the fit was excellent and the shims well chosen to start. But in a pinch, either by time, distance, or cash... the pole and bridle could work for you...

Commotion

Member II

Foss Rudder on my E35-2

I am installing a new Foss rudder and found that the bump on the top was nowhere near flush to the post, (therefore, not full contact with the bushing either) Attached photo... I will post all of the photos of the Vesconite bushing modifications in the next day or two. So far, very happy with the progress and how I believe this will work out.

I am installing a new Foss rudder and found that the bump on the top was nowhere near flush to the post, (therefore, not full contact with the bushing either) Attached photo... I will post all of the photos of the Vesconite bushing modifications in the next day or two. So far, very happy with the progress and how I believe this will work out.

Attachments

You're going to install a SECOND bushing right?

You're going to install a SECOND bushing right? Not cut the existing bushing to fit the slope of the rudder?

My concern is that the bottom rudder bearing which is shown in the photo does not turn, if you mod it to fit the out of plane rudder top, the rudder is going to jam when it is turned. You would in effect be creating a locking cam system, which is exactly counter to what we want on a rudder.

Guy

You're going to install a SECOND bushing right? Not cut the existing bushing to fit the slope of the rudder?

My concern is that the bottom rudder bearing which is shown in the photo does not turn, if you mod it to fit the out of plane rudder top, the rudder is going to jam when it is turned. You would in effect be creating a locking cam system, which is exactly counter to what we want on a rudder.

Guy

Commotion

Member II

Yes, that's the plan... Thanks for looking out for me

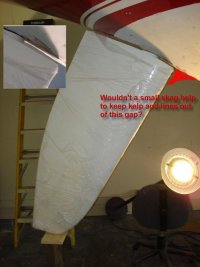

Yes, thank you. I installed a second bushing and epoxied it into the top of the rudder. Is there going to be a problem with corrosion on the shaft. Anything I should do to make sure I have a water tight seal at the top of the rudder to avoid water intrusion inside the foam rudder? I epoxied West Systems 404 encapsulating a 3" long vesconite bushing. (This was done last night and is not reflected in the attached photo) I can post new photos. Perhaps a new thread? How much gap do I need between the top of the rudder and the hull? I believe a small gap is better, yes? Wouldn't a small skag on the leading edge of the rudder help keep objects out of the gap in the rudder? As always, any help or comments are greatly appreciated.

Thanks again,

Commotion (Rick)

Yes, thank you. I installed a second bushing and epoxied it into the top of the rudder. Is there going to be a problem with corrosion on the shaft. Anything I should do to make sure I have a water tight seal at the top of the rudder to avoid water intrusion inside the foam rudder? I epoxied West Systems 404 encapsulating a 3" long vesconite bushing. (This was done last night and is not reflected in the attached photo) I can post new photos. Perhaps a new thread? How much gap do I need between the top of the rudder and the hull? I believe a small gap is better, yes? Wouldn't a small skag on the leading edge of the rudder help keep objects out of the gap in the rudder? As always, any help or comments are greatly appreciated.

Thanks again,

Commotion (Rick)

Attachments

Last edited:

Yes a small skeg here is helpfull

You can make one out of a bit of SS rod for all that it matters though... The full skeg is really not all that necessary. You can do that without any holes in the hull. Epoxy and a bent piece of SS rod would work well... (There could be issues with the rod needing a small zinc, on it, but I don't know that I would worry about it.... As it is only there for a bumper if you had to redo it every other haul out it would not be a problem.

This is an area to collect fish trap lines and fishing lines, and nets and a whole lot of shit, including sea weed.!

Guy

You can make one out of a bit of SS rod for all that it matters though... The full skeg is really not all that necessary. You can do that without any holes in the hull. Epoxy and a bent piece of SS rod would work well... (There could be issues with the rod needing a small zinc, on it, but I don't know that I would worry about it.... As it is only there for a bumper if you had to redo it every other haul out it would not be a problem.

This is an area to collect fish trap lines and fishing lines, and nets and a whole lot of shit, including sea weed.!

Guy

Commotion

Member II

Re: Yes a small skeg here is helpfull

Thank you, that is a great idea..., but, I already started... I took a small piece of 1/4" Hydrotech, shaped it in the profile I thought would make a good skeg, wet that in West Systems, then 404'd that to the hull, (no screws) then encapsulated and faired it in in 404. Going cover that with Bi-Axial glass. I will barrier coat it at the same time I do the complete bottom with Interlux 2000. I will post photo's (if anyone is interested) with the rudder bushing modifications. So far, it looks like it will work.

I have a concern about the Foss rudder shaft. It is just pipe (and I sure hope that thing is 316 and not 304). If I understand correctly, if stainless does not breath or have a water exchange, it will build up acid (?) and oxidize. The old rudder had a lot of rust, right at the top of the rudder where the post enters the top of the rudder. Is this because it was next to a bronze bushing or because the boat sat in the slip as a liveaboard and did not have regular water exchange? A friend of mine said, to pack the thing in water resistant grease in the complete rudder tube and that will help keep corrosion down. Does that work? Would a zinc at the top side of the rudder on one or both sides near the shaft help? Any good advice at this stage is appreciated. (or am I worried about nothing?)

Thanks again,

Rick (Commotion E-35-2)

Thank you, that is a great idea..., but, I already started... I took a small piece of 1/4" Hydrotech, shaped it in the profile I thought would make a good skeg, wet that in West Systems, then 404'd that to the hull, (no screws) then encapsulated and faired it in in 404. Going cover that with Bi-Axial glass. I will barrier coat it at the same time I do the complete bottom with Interlux 2000. I will post photo's (if anyone is interested) with the rudder bushing modifications. So far, it looks like it will work.

I have a concern about the Foss rudder shaft. It is just pipe (and I sure hope that thing is 316 and not 304). If I understand correctly, if stainless does not breath or have a water exchange, it will build up acid (?) and oxidize. The old rudder had a lot of rust, right at the top of the rudder where the post enters the top of the rudder. Is this because it was next to a bronze bushing or because the boat sat in the slip as a liveaboard and did not have regular water exchange? A friend of mine said, to pack the thing in water resistant grease in the complete rudder tube and that will help keep corrosion down. Does that work? Would a zinc at the top side of the rudder on one or both sides near the shaft help? Any good advice at this stage is appreciated. (or am I worried about nothing?)

Thanks again,

Rick (Commotion E-35-2)