Akavishon

Member III

Alright then, it's mid-winter here in Boston, wicked cold, but time to start getting my act together for next season

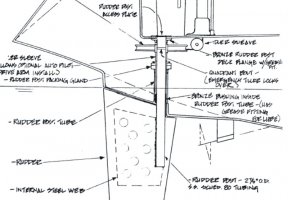

Last summer, I had lots of water coming in up the rudder post tube and leaking UNDER the lower rim of the packing gland. This would happen mostly when motoring at 4+ knots, or when the cockpit was heavily loaded with meatgrinding crew ... I whined about it, but did nothing to fix it.

When I inspected the rudder packing gland, I found that a) it's badly corroded; b) it can't be tightened any further; c) the LOWER half of the gland is freely turning on top of the rudder post tube (!).

I'm not very mechanically talented, but - isn't the lower half of the packing gland supposed to be glassed into the rudder post tube? Clearly, it must have broken free, allowing water in?

So, my plan of action:

1. Order a new packing gland, maybe from here

2. Unmount the quadrant, drop the rudder - maybe not all the way (boat is on dry, but not sure high enough), but just enough to clear the packing gland

3. Glass/epoxy the packing gland onto the rudder post tube

4. Assemble everything and grease the zercs

I'm wondering if this is something I should do myself, or let the yard handle it ... any insights/guidance from fellow Vikings?

TIA - Zoran

Last summer, I had lots of water coming in up the rudder post tube and leaking UNDER the lower rim of the packing gland. This would happen mostly when motoring at 4+ knots, or when the cockpit was heavily loaded with meatgrinding crew ... I whined about it, but did nothing to fix it.

When I inspected the rudder packing gland, I found that a) it's badly corroded; b) it can't be tightened any further; c) the LOWER half of the gland is freely turning on top of the rudder post tube (!).

I'm not very mechanically talented, but - isn't the lower half of the packing gland supposed to be glassed into the rudder post tube? Clearly, it must have broken free, allowing water in?

So, my plan of action:

1. Order a new packing gland, maybe from here

2. Unmount the quadrant, drop the rudder - maybe not all the way (boat is on dry, but not sure high enough), but just enough to clear the packing gland

3. Glass/epoxy the packing gland onto the rudder post tube

4. Assemble everything and grease the zercs

I'm wondering if this is something I should do myself, or let the yard handle it ... any insights/guidance from fellow Vikings?

TIA - Zoran