Hello all, I used a messenger line over the winter when my boat was on the hard. When swapping out, my "quick" connection (still sewn & taped) came off, thus my main halyard came off the mast. Because my boat (E33RH) is fractionally rigged, climbing up to masthead is not an option, thus ended up hiring a "cherry picker" crane next week to go up to the top. (You can imagine how I felt: if I spent 5 more min doing a better job on connecting the lines, I would not have to spend $$$ and more energy!) Would appreciate any advice & comments (and share your stories please!):

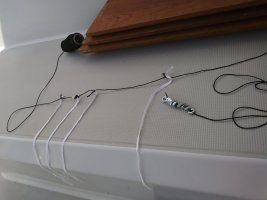

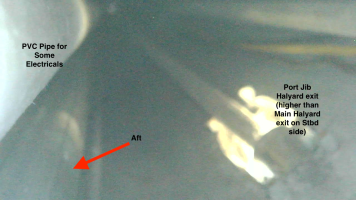

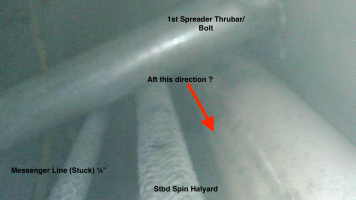

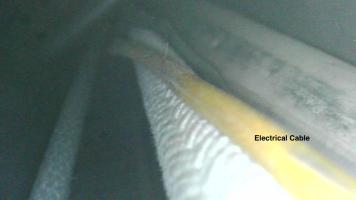

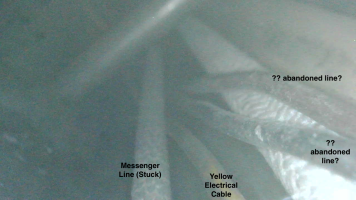

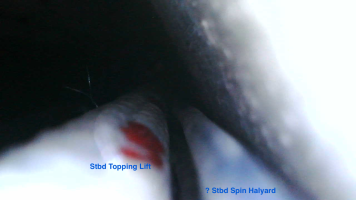

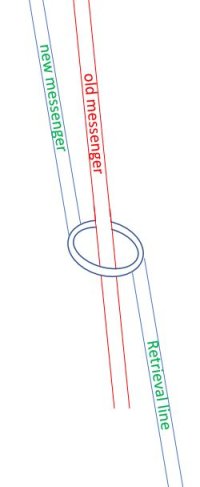

1. To thread the main halyard, planning on using a bicycle chain tied to either messenger line or the actual halyard. Mostly concerned about making sure it will not be caught by other lines (4 other halyards in the mast below forestay) or fittings inside. Other halyards are all metal wires inside thus might not be as bad. Any thoughts?

2. The halyard exit cover opening is only about 15-20mm wide...do I really need to take this off? I am hoping to use a magnet stick to fish out the chain.

3. One saving grace is that I've been meaning to remove the running back stays (RBS) and old Lazy Jack (LJ) lines, thus this will be a good opportunity. Any thoughts on best approach? Currently, planning on leaving the fittings but just cutting wires right below the fittings.

4. When on the top of the mast, what are the other service items I can do besides visually inspecting instruments?

What are other things to consider for this project?

Thank you!

sf1332

s/v "Karma" 1982 E33RH #12

Erie & Pittsburgh, PA

1. To thread the main halyard, planning on using a bicycle chain tied to either messenger line or the actual halyard. Mostly concerned about making sure it will not be caught by other lines (4 other halyards in the mast below forestay) or fittings inside. Other halyards are all metal wires inside thus might not be as bad. Any thoughts?

2. The halyard exit cover opening is only about 15-20mm wide...do I really need to take this off? I am hoping to use a magnet stick to fish out the chain.

3. One saving grace is that I've been meaning to remove the running back stays (RBS) and old Lazy Jack (LJ) lines, thus this will be a good opportunity. Any thoughts on best approach? Currently, planning on leaving the fittings but just cutting wires right below the fittings.

4. When on the top of the mast, what are the other service items I can do besides visually inspecting instruments?

What are other things to consider for this project?

Thank you!

sf1332

s/v "Karma" 1982 E33RH #12

Erie & Pittsburgh, PA