Jeff Asbury

Principal Partner

This was a private message sent to me that I did not have the answer to. Please help.

Jeff,

I am about to haul my E27 ( #213 Holomoku in Honolulu)and hope to fix the chronic leak at my packing gland. I have lived with the leaking for a while but am taking this opportunity to fix the problem. I have been unable to replace the packing as the shaft log is so close to the pacing nut ,when loosened, that there is not enough space to remove the old packing.(after two hours laying on top of the engine etc etc....) I will be pulling the shaft so access should not be a problem. I am hoping to replace the existing unit with a PSS shaft seal if they make one for a 3/4 shaft.... Do you have any thoughts or suggestions regarding the process? What has been your experience?.... Aloha, Tom

Hi Tom,

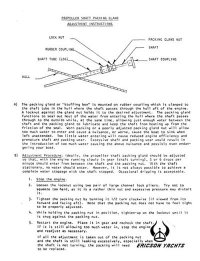

To answer your question I had a Marine Mechanic friend help me with my tightening my packing gland. Number one is because I did not have the right tools, number two is because I lacked the experience. I am sure you are aware that it is supposed to leak a little. I am concerned that mine doesn't leak enough. I get salt crystals around mine and I speculate it is because the heat of the friction of the prop shaft is drying the salt water as it leaks out. I am not too concerned because there is always a small amount of water right under it. I am attaching both JPGs of the Packing Gland Adjustment guide from the Specs and Docs section from the EYO site. I will also post your question in the mechanical and maintenance section to see who else might have better advice. When I tried it my self I had the same problems as you. It is a very tight space to work in. You need a good pipe wrench and a large channel lock with short handles.

Jeff

Jeff,

I am about to haul my E27 ( #213 Holomoku in Honolulu)and hope to fix the chronic leak at my packing gland. I have lived with the leaking for a while but am taking this opportunity to fix the problem. I have been unable to replace the packing as the shaft log is so close to the pacing nut ,when loosened, that there is not enough space to remove the old packing.(after two hours laying on top of the engine etc etc....) I will be pulling the shaft so access should not be a problem. I am hoping to replace the existing unit with a PSS shaft seal if they make one for a 3/4 shaft.... Do you have any thoughts or suggestions regarding the process? What has been your experience?.... Aloha, Tom

Hi Tom,

To answer your question I had a Marine Mechanic friend help me with my tightening my packing gland. Number one is because I did not have the right tools, number two is because I lacked the experience. I am sure you are aware that it is supposed to leak a little. I am concerned that mine doesn't leak enough. I get salt crystals around mine and I speculate it is because the heat of the friction of the prop shaft is drying the salt water as it leaks out. I am not too concerned because there is always a small amount of water right under it. I am attaching both JPGs of the Packing Gland Adjustment guide from the Specs and Docs section from the EYO site. I will also post your question in the mechanical and maintenance section to see who else might have better advice. When I tried it my self I had the same problems as you. It is a very tight space to work in. You need a good pipe wrench and a large channel lock with short handles.

Jeff