simdim

Member II

Folks,

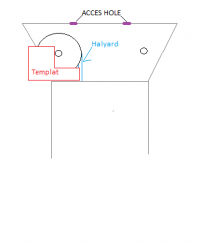

While the mast is down I am installing mast step rigging plate and replacing halyards from wire to ropes. I know that this had been asked and answered, however here it goes again:

Original sheaves in the mast box are OD 2 3/4 with ID 3/8 and are in a bad shape. Each halyard is using two sheaves and feels like one too many to me.

I had surveyed available sheaves and the best fit is Garhauer 27MH - it is smaller 2" vs 2 3/4" however it is the same ID. Going with smaller sheaves should allow me to go with cheaper 3/8" XLE rope insted of 5/16 Spectra from Cajun Trading(Thanks to Rhynie for the tip).

Is there a better solution? Should I try to move to single sheave configuration?

While the mast is down I am installing mast step rigging plate and replacing halyards from wire to ropes. I know that this had been asked and answered, however here it goes again:

Original sheaves in the mast box are OD 2 3/4 with ID 3/8 and are in a bad shape. Each halyard is using two sheaves and feels like one too many to me.

I had surveyed available sheaves and the best fit is Garhauer 27MH - it is smaller 2" vs 2 3/4" however it is the same ID. Going with smaller sheaves should allow me to go with cheaper 3/8" XLE rope insted of 5/16 Spectra from Cajun Trading(Thanks to Rhynie for the tip).

Is there a better solution? Should I try to move to single sheave configuration?