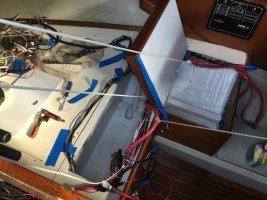

We have a 1982 E38 and are sailing around the Sea of Cortez for a few years with our kids. Putting the boat away for the summer in Mexico I am going through everything to figure out what needs to be repaired. The manual bilge is not operating. There is a ~1-1/2" OD gray flexible hose (wire coiling to prevent crimping) that enters the bilge. It has an inch of exposure and there is a smaller, white pvc hose inserted into the larger gray hose and it looks like someone tried to silicon the seal and use a hose clamp. The white pvc hose then goes to the bottom of the bilge (without a strainer). The seal between the two hoses is broken so the bilge pump is not getting suction.

Seems like a poor system to me so I was wondering what others with the same boat have? I can always run a new flex hose all the way from the manual pump to the bilge, but access is difficult. Thanks for any suggestions.

Seems like a poor system to me so I was wondering what others with the same boat have? I can always run a new flex hose all the way from the manual pump to the bilge, but access is difficult. Thanks for any suggestions.