Hello,

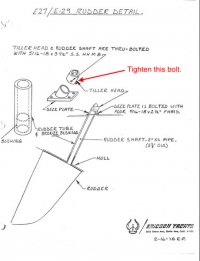

I have an 1973 Ericson 27 and there is 'considerable' play in the tiller. It's coming from where the metal bracket that forms the end of the tiller attaches to the big bronze top of the rudder post (ie the bolt 'hinge' that allows the tiller to move up and down). The bearings associated with the rudder itself seem tight.

I've started a bit of racing the play has moved from the 'annoying' to 'problem' category.

Previous investigation revealed that the bolt hole that attaches the tiller is rounded into an hour-glass shape, allowing movement. Last year I drilled this hole a bit bigger (it was 3/8" (9.5mm) and I upped it to 10mm). This and some new washers helped a little, but it's still pretty wobbly.

I could drill it even bigger, but I'm afraid of weakening the attachment point. I can tighten the bolts really hard and reduce wobble this way, but this makes the tiller tight to move up and down, works loose in a month or so, and makes me concerned that I'm going to damage the bracket on the tiller as I'm basically squeezing it shut.

Is there a recommended fix for this? I had originally tried to find some sort of sleeve to 'un-taper' the holes, but couldn't find anything.

Is it safe to drill this noticeably bigger (7/16", 1/2")?

Is there a way to restore the holes to a less hour-glass shape (without trapping undo moisture or inducing corrosion with mismatched metals)? This must be a problem solved by folks over the centuries...

Cheers,

Ed

I have an 1973 Ericson 27 and there is 'considerable' play in the tiller. It's coming from where the metal bracket that forms the end of the tiller attaches to the big bronze top of the rudder post (ie the bolt 'hinge' that allows the tiller to move up and down). The bearings associated with the rudder itself seem tight.

I've started a bit of racing the play has moved from the 'annoying' to 'problem' category.

Previous investigation revealed that the bolt hole that attaches the tiller is rounded into an hour-glass shape, allowing movement. Last year I drilled this hole a bit bigger (it was 3/8" (9.5mm) and I upped it to 10mm). This and some new washers helped a little, but it's still pretty wobbly.

I could drill it even bigger, but I'm afraid of weakening the attachment point. I can tighten the bolts really hard and reduce wobble this way, but this makes the tiller tight to move up and down, works loose in a month or so, and makes me concerned that I'm going to damage the bracket on the tiller as I'm basically squeezing it shut.

Is there a recommended fix for this? I had originally tried to find some sort of sleeve to 'un-taper' the holes, but couldn't find anything.

Is it safe to drill this noticeably bigger (7/16", 1/2")?

Is there a way to restore the holes to a less hour-glass shape (without trapping undo moisture or inducing corrosion with mismatched metals)? This must be a problem solved by folks over the centuries...

Cheers,

Ed