Cool

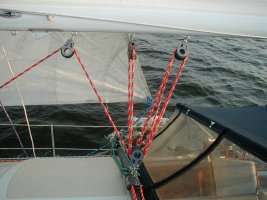

Ben, for this cunn. setup you could tie off some 3/16 or so spectra/kevlar line to the ring you are running the cunn line through. Then run it up through the webbing and back down through that ring, and just make a bowline in the end of it. The cunn purchase can attach to that bowline-like it now attaches to the rope running through the webing, so you have everything one one side as it us now, just that your purchase is pulling on the doubler line, not the sail. Voila!

As for the loose slides on the foot, I think what was happening is that they were binding, so that is why you were having all the load right at the clew. Ideally, they would slide freely in the boom track so the foot had equal load along the entire length. This will no longer be a problem

Regarding trim-this is a perfect technique-especially for a composite mainsail. What you DON'T want is (as you say) is to have so much halyard load than when you ease the sheet off for any reason you don't jam the draft up to the mast (btw-you expressed that VERY well!!) If with anything more than a hand tight halyard in light-med air you have the problem of the draft up against the mast, then yes, continue, and use the cunningham to fine tune.......On windy days you may need a little more. The only possible concern is that the main is at or near the band. If you had to keep the sail 6" low to keep things looking right, the sail may have a minor design problem, but if all this is happening as you say and the main is within an inch of the band, then don't change.

Yes, wrinkles are just fine if that is what it takes to keep the draft in the right place. Having the draft too far forward is MUCH slower than a few wrinkles!!

You are fine-just remember to use that cunningham to keep the draft right. If you want to remove wrinkles, just make sure that in doing so you don't move things too far fwd..

Have I repeated myself enough?

Seeya,

S