Cast Acrylic and Insulated Hatch Covers

Hi John,

This thread has info on polycarbonate (lexan) vs acrylic (plexiglass) and also on Select Plastics who's website has plenty of info on all aspects (sealers, gaskets, glue for gaskets) of hatch repair. They can also do the re-furb if you can't.

http://www.ericsonyachts.org/infoex...-quot-Acrylic-vs-1-2-quot-Polycarbonate/page2

Unless Lexan has gotten a lot more UV resistant, I think cast acrylic (not extruded) is generally recommended for hatches. Lexan is also more flexible which is a problem for sealing in the frame designed for stiffer acrylic and a surface that you load up by walking on.

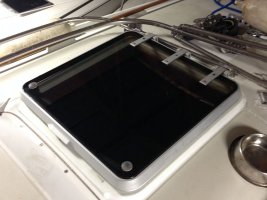

I just did my two Atkins - Hoyle hatches last winter with cast acrylic. I had the lenses cut locally by my local shop, Maritime Plastics in Annapolis, and did the rest myself. A non-marine specific plastic shop will be cheaper for the acrylic. I also think you can cut you acrylic yourself if you desire. I'm planning on cutting my single piece acrylic companionway board myself.

The hardest part of the job, by far, was cleaning out the old sealant. Your wood framed hatches should be a much easier clean up. Not a hard job and well worth the results. I replaced my gaskets as well. All the materials are available online or from a plastics shop.

My local shop, Maritime Plastics in Annapolis, changed my mind from using clear for the overhead hatches. They said they had never made hatches in clear. I had black hatch covers so I thought clear would let more light in during the winter months and cloudy days. I didn't want something really odd for my hatches when I sell the boat (even if it might be a better idea) so I went for the typical tint level (#2412) in a bronze. It's similar in tint level to the #2064 tint in grey that I have for my ports. Now that it's winter, I don't regret getting tinted vs clear lenses. The tint lets in plenty of light. Also, I never notice that my hatches are bronze tint and my ports are grey.

As for hatch covers. I switched to light tan covers from my old black ones. I also had a 1/2 inch closed cell foam pad added in a pocket under the top surface. My plastic guy says it's mostly thermal stresses that craze the lenses. The dark tinted acrylic heats up in the sun and then gets quickly cooled and micro cracks when it rains (or you hit it with the hose). He said the insulation was a great idea. In the tropics this is a bigger problem with more sun and more thunder showers, so they have gone from dark tinting to white frosted acrylic on horizontal surfaces like skylights and hatches where you want light but don't need to see through. The frosting acts like tinting but it absorbs much less heat and if it slowly starts crazing it's not visible. See posts #6 and #10 of this thread for experience with insulated hatch covers:

http://www.ericsonyachts.org/infoexchange/showthread.php?7120-Lewmar-replacement-acrylic-1988

Let me know if you have any questions.

Mark