bsangs

E35-3 - New Jersey

The crazy rain we had here in NJ - started Friday, didn't stop until about 2 am today - kept filling my bilge through the mast. My marina neighbor texted me about 8 pm last night to let me know the high water alarm I installed properly last week (thank God) was going off. He went over to check things out and my centrifugal bilge pump was spinning, but not removing any water. First time that's ever happened, so figured the pump had burned itself out and needed to be changed. No problem, as I have a couple on hand. So wife and I bolted over to marina in the driving rain to check out the issue. Took the pump off, checked and cleaned the debris screen and impeller, ran a couple tests and it was operating correctly, but not moving any water. Tried the manual Whale gusher pump from the cockpit, it also wasn't moving any water. Hmmm.

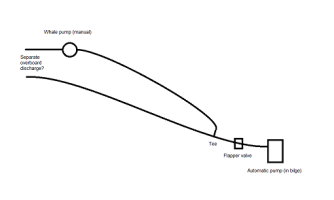

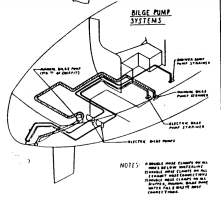

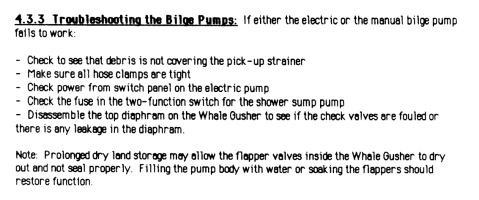

I remembered fooling around last summer, trying to get an understanding of the bilge system, when I discovered a flapper valve leading to the "T" where the automatic and manual bilge pump hoses meet. It prevents water from the automatic pump going into the manual pump bilge chamber as it passes out to the exit. Took the manual bilge pickup hose off, pushed the flapper valve back, water came out (not too much), and then I decided to try the automatic pump again, and it worked properly, draining the bilge. Put everything back together, but wanted to check the manual pump again. Filled the bilge, went to the cockpit, pumped until my arm got sore, then my wife did the same, and nothing came through the manual pump. Makes its pumping/sucking noises, but no water.

So, two questions: 1) Why did the automatic pump not remove any water before I checked that flapper valve? Is that an example of the dreaded "air lock" I've read about, but never experienced? 2) Where do I start in diagnosing why the manual pump isn't pulling out any water? I believe it worked last year when I tested it, but have never had to use it since. Outside of the pickup hose, it shares the same hoses as the automatic, so I'm pretty sure there's no blockage in the hose. The manual Whale gusher pump was installed by the previous owner, and is less than 10 years old, so I wouldn't think it would fail already. Stumped!

I remembered fooling around last summer, trying to get an understanding of the bilge system, when I discovered a flapper valve leading to the "T" where the automatic and manual bilge pump hoses meet. It prevents water from the automatic pump going into the manual pump bilge chamber as it passes out to the exit. Took the manual bilge pickup hose off, pushed the flapper valve back, water came out (not too much), and then I decided to try the automatic pump again, and it worked properly, draining the bilge. Put everything back together, but wanted to check the manual pump again. Filled the bilge, went to the cockpit, pumped until my arm got sore, then my wife did the same, and nothing came through the manual pump. Makes its pumping/sucking noises, but no water.

So, two questions: 1) Why did the automatic pump not remove any water before I checked that flapper valve? Is that an example of the dreaded "air lock" I've read about, but never experienced? 2) Where do I start in diagnosing why the manual pump isn't pulling out any water? I believe it worked last year when I tested it, but have never had to use it since. Outside of the pickup hose, it shares the same hoses as the automatic, so I'm pretty sure there's no blockage in the hose. The manual Whale gusher pump was installed by the previous owner, and is less than 10 years old, so I wouldn't think it would fail already. Stumped!