As long as we are talking about spaces and capacities, permit me to drift a bit to a topic that many E34 owners may have faced.

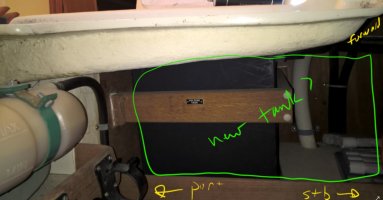

The battery compartment in the E34 just fits two group 27 batteries, and I mean, just fits, no extra room whatsoever. I combined both those batteries into one house bank and installed a group 24 starting battery nearby in the space next to the prop shaft. I bought a battery box to fit and epoxied it in place, no problem there.

But I have too many small gauge wires going to the terminals of the house bank; 1 kW inverter, battery charger, both port and starboard refers, Balmar smart gauge, Balmar charging relay, and bilge pump, and all their respective grounds. All are fused but the mess of wires is a pain. I would like to install two terminal strips (+ and -) to make better access to the batteries, i.e. water check and addition, removal, etc. Any ideas where to mount such terminal strips, there is absolutely no room inside the battery compartment. Do I need to cut a section out of the aft berth platform? The terminal strips need to be before the main battery switch so mounting such strips in the engine compartment and then having to route back to the main battery switch is pain.