A question for @Christian Williams, in the forum for the sake of general consumption:

I have recently joined the prestigious and exclusive club of people who have broken their Kenyon boom aluminum gooseneck castings. I have been able to order a replacement from Rig-Rite and plan to add a set of reinforcing plates for good measure.

Here is Christian's blog entry about the plates he installed to serve the same purpose:

ericsonyachts.org

ericsonyachts.org

Here is another thread where a member had a gooseneck fabricated/repaired with stainless steel:

ericsonyachts.org

ericsonyachts.org

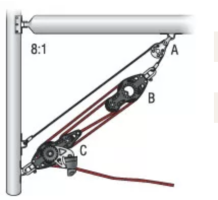

My question for Christian is if you could provide a photo at your convenience of how you have aligned the plates on either side of the gooseneck. I see some washers pictured here on the forward bolt but they appear loose. Do you have a big stack of washers on the aftmost bolts? I presume if the middle bolts are tightened you must have an bushing that is permitting the reefing sheaves to turn freely.

On my gooseneck, the reefing sheave bolts are in one plane, the gooseneck attachment is in a second, and the reinforcing bridge of aluminum between the bolt holes is in a third (the widest one, over which the plates must pass).

A photo of the underside of the gooseneck fitting as mounted would be helpful. Thanks in advance.

I have recently joined the prestigious and exclusive club of people who have broken their Kenyon boom aluminum gooseneck castings. I have been able to order a replacement from Rig-Rite and plan to add a set of reinforcing plates for good measure.

Here is Christian's blog entry about the plates he installed to serve the same purpose:

E381 - Broken Boom Gooseneck Fitting (Fixed), Thelonious II

Video: The connection of the boom to the mast--the gooseneck--is subject to compression and to forces on both axes, yet is frequently taken for granted. It's subject to failure, a jury rig is a challenge, and even professional repair is...

Here is another thread where a member had a gooseneck fabricated/repaired with stainless steel:

Kenyon gooseneck

WANTED: Kenyon gooseneck Would anybody per chance have a spare Kenyon gooseneck K-43002 and be willing to part with it? I believe they came on E34, E35, and E38s. They are for the Kenyon 3756 booms. Here's the link...

My question for Christian is if you could provide a photo at your convenience of how you have aligned the plates on either side of the gooseneck. I see some washers pictured here on the forward bolt but they appear loose. Do you have a big stack of washers on the aftmost bolts? I presume if the middle bolts are tightened you must have an bushing that is permitting the reefing sheaves to turn freely.

On my gooseneck, the reefing sheave bolts are in one plane, the gooseneck attachment is in a second, and the reinforcing bridge of aluminum between the bolt holes is in a third (the widest one, over which the plates must pass).

A photo of the underside of the gooseneck fitting as mounted would be helpful. Thanks in advance.