alexwilliamrussell

Member II

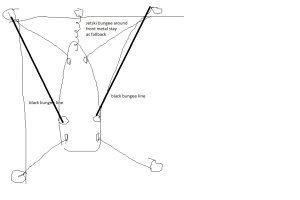

My E25 has just 2 cleats and 1 of mine had to be repaired, so I think I want to direct anchor force downward and equally so may just loop anchor rope UNDER but NOT TIED to the cleats with the rope tied to make a loop 10 feet forward and then the anchor line continuing 30 feet more to the Anchor. I guess this will rub and wear the top of the bow deck, but I can notice and stop if that occurs. I think arranging to split anchor rope and go to the 2 cleats seperately would be more complex and not as good since will pull on 1 cleat then the other each minute. Any thoughts?