Hey, my Ericson peeps! Can anyone tell me how to fix this?

I'm thinking, dry out all the pieces, sand off the old adhesive, glue back into place with wood glue.

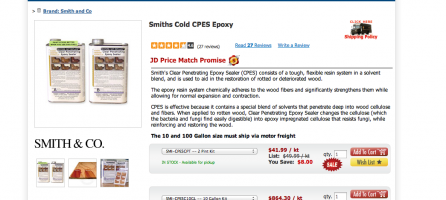

Seems like if I don't use something more substantial it's just going to pop back out, especially since it's right outside the head and gets a lot of water on it.

Thanks in advance!

Ed

Kinnaree

'91 E-34

I'm thinking, dry out all the pieces, sand off the old adhesive, glue back into place with wood glue.

Seems like if I don't use something more substantial it's just going to pop back out, especially since it's right outside the head and gets a lot of water on it.

Thanks in advance!

Ed

Kinnaree

'91 E-34