Hello all,

as our season ends, I am thinking about one of our planned fall projects - rerouting the fuel vent hose.

It takes over a minute to add one gallon to our tank. If we exceed this rate, fuel begins to overflow. We have traced our problem to the fuel vent line (when I remove the fuel gauge on the tank to allow air to enter the tank, we can fill the tank at a normal rate).

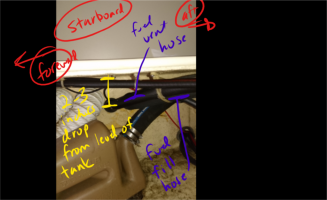

The vent/hull fitting is clean. But there is a 2-3 inch vertical drop in the hose after the hose leaves our tank (see attachment 1). This drop in hose is consistently filling with fuel (maybe when the boat pitches). Once the drop in the hose is filled, we again have a problem with the rate of fuel fill.

We think we have a solution but I would appreciate a sanity check.

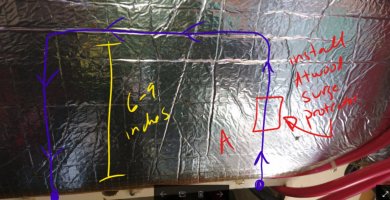

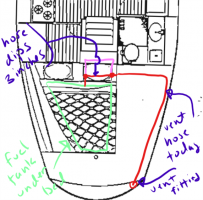

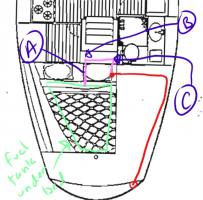

Please see attachment 2 & 3. We are planning to extend the vent hose forward, loop it 6-9 inches up into the aft end of the engine compartment, then loop it back down to enter its original exit hole in the starboard lazarette. We also plan to add an Atwood anti-surge fitting at point A to minimize the chance of any fuel entering the downward part of the tube.

Can anyone see an obvious problem with this arrangement? Any suggestions?

https://www.amazon.com/Attwood-Fuel-Vent-Surge-Protector/dp/B0000AZ7PE?SubscriptionId=AKIAJ7T5BOVUVRD2EFYQ&tag=camelhomerecent-20&linkCode=xm2&camp=2025&creative=165953&creativeASIN=B0000AZ7PE

as our season ends, I am thinking about one of our planned fall projects - rerouting the fuel vent hose.

It takes over a minute to add one gallon to our tank. If we exceed this rate, fuel begins to overflow. We have traced our problem to the fuel vent line (when I remove the fuel gauge on the tank to allow air to enter the tank, we can fill the tank at a normal rate).

The vent/hull fitting is clean. But there is a 2-3 inch vertical drop in the hose after the hose leaves our tank (see attachment 1). This drop in hose is consistently filling with fuel (maybe when the boat pitches). Once the drop in the hose is filled, we again have a problem with the rate of fuel fill.

We think we have a solution but I would appreciate a sanity check.

Please see attachment 2 & 3. We are planning to extend the vent hose forward, loop it 6-9 inches up into the aft end of the engine compartment, then loop it back down to enter its original exit hole in the starboard lazarette. We also plan to add an Atwood anti-surge fitting at point A to minimize the chance of any fuel entering the downward part of the tube.

Can anyone see an obvious problem with this arrangement? Any suggestions?

https://www.amazon.com/Attwood-Fuel-Vent-Surge-Protector/dp/B0000AZ7PE?SubscriptionId=AKIAJ7T5BOVUVRD2EFYQ&tag=camelhomerecent-20&linkCode=xm2&camp=2025&creative=165953&creativeASIN=B0000AZ7PE