Rudder mods

Rob,

I did a custom rudder mod several years ago on my '72 E-35 MKII. The plans came from California Custom Yacht Design (CCYD) for 25.00. He had worked up a NACA profile that is akin to an airplane wing and about 14" longer as well. He provided two options: totally new rudder, or modify the current one after stripping all the foam off and asuming in god shape. I went the totally new route and am quite pleased; turns on a dime, weather helm is much, much less and I can actually back down now.

Upon discussions with CCYD, I was told that in order to save money, Ericson placed the 32 rudder on the 35 and used A-4's instead of the Westerbeke diesel that was designed in. Bruce King was supposedly irate that Ericson dropped in another rudder and lightened the boat by a hunderd pounds or so by putting in the A-4 instead. Rumors? possibly, but with the new rudder it handles MUCH better and the A-4 has been a little wimpy at times with just 25 hp. Plus the boat could use a couple hundred pounds right about under the companionway steps (install bigger batteries instead in that location?). Anyway, my $0.02 worth.

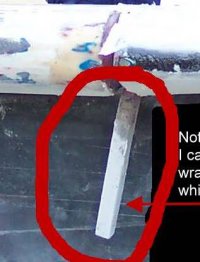

See before and after shots below.

John M