You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

EGregerson

Member III

cutlass

I wish i could say i've done that, but I was planning to on my xp25; in researching the project (on this site and others) it seems very doable; u might want a yard estimate to get an idea of what u would save. The rudder might have to be dropped, and then the prop shaft removed; the bugger will be getting the flange (with set screw)(soak the bolts with penetrating oil)(I had one bolt shear off and had to drill it out) off. Apparently, the bearing itself can be cut out with a hack saw blade from the inside. Then insert the new bearing with threaded rod, washers and nut to seat it. Good luck whatever way u go.

ps; i took the rudder removal opportunity to put bronze shim stock in the rudder log to take up slack; and lube the upper shaft and steering apparatus.

I wish i could say i've done that, but I was planning to on my xp25; in researching the project (on this site and others) it seems very doable; u might want a yard estimate to get an idea of what u would save. The rudder might have to be dropped, and then the prop shaft removed; the bugger will be getting the flange (with set screw)(soak the bolts with penetrating oil)(I had one bolt shear off and had to drill it out) off. Apparently, the bearing itself can be cut out with a hack saw blade from the inside. Then insert the new bearing with threaded rod, washers and nut to seat it. Good luck whatever way u go.

ps; i took the rudder removal opportunity to put bronze shim stock in the rudder log to take up slack; and lube the upper shaft and steering apparatus.

For me, I had the choice of squeezing in behind the engine, separating the shaft from the coupler, then getting the shaft past the rudder, slicing the bearing and pulling it out, then reversing the procedure. Or paying the yard about an hours labor, having them use a specialized tool and being done with it.

Turned out to be not that hard of a decision after all. I like to do my own work, but the right tool makes all the difference here.

Don Wigle

Wiggle Room

E38 #8

Pt. Richmond, CA

Turned out to be not that hard of a decision after all. I like to do my own work, but the right tool makes all the difference here.

Don Wigle

Wiggle Room

E38 #8

Pt. Richmond, CA

The right tool for the job.

Don and all, Sometimes the right tool for the job is a checkbook. At times it's not important for me to actually do the job but just know how to do it and know I could if pushed to do so. Glyn Judson, E31 hull #55, Marina del Rey CA

Don and all, Sometimes the right tool for the job is a checkbook. At times it's not important for me to actually do the job but just know how to do it and know I could if pushed to do so. Glyn Judson, E31 hull #55, Marina del Rey CA

Tom Metzger

Sustaining Partner

There are several good threads on this site for doing it yourself, and several of us have done it without removing the rudder or shaft. It can be a spendy job if the yard does it.

It's really a shame we don't all have access to Glyn's checkbook.

One good thread is:

http://www.ericsonyachts.org/infoexchange/showthread.php?t=9267

It's really a shame we don't all have access to Glyn's checkbook.

One good thread is:

http://www.ericsonyachts.org/infoexchange/showthread.php?t=9267

$$$$$

For reference, my cutlass was starting to spin in the strut, so some extra work was needed, but the bill reads:

Replace cutlass bearing, drill strut, add zinc. Drill, tap and install set screws in strut to secure cutlass bearing....3 hrs @ 105 per.

So at $315, definitely not cheap. Set screws were added to prevent further spinning of the bearing, they added a zinc to the strut as there was some corrosion happening. Sure cut down on vibration though.

Don

For reference, my cutlass was starting to spin in the strut, so some extra work was needed, but the bill reads:

Replace cutlass bearing, drill strut, add zinc. Drill, tap and install set screws in strut to secure cutlass bearing....3 hrs @ 105 per.

So at $315, definitely not cheap. Set screws were added to prevent further spinning of the bearing, they added a zinc to the strut as there was some corrosion happening. Sure cut down on vibration though.

Don

Replacing a cutlass bearing the easy way.

Tom, Don and all, My dive service has the tools to remove and replace a cutlass beating with the boat IN THE WATER. As well, they have the ability to remove the prop as a part of that same job. It's some sort of hydraulic device that presses the old bearing out and pushes the new one in obviously thus the need for the prop to be off. It's a pretty neat tool given that mine took say,30 minutes start to finish right in the slip. Glyn

Tom, Don and all, My dive service has the tools to remove and replace a cutlass beating with the boat IN THE WATER. As well, they have the ability to remove the prop as a part of that same job. It's some sort of hydraulic device that presses the old bearing out and pushes the new one in obviously thus the need for the prop to be off. It's a pretty neat tool given that mine took say,30 minutes start to finish right in the slip. Glyn

Glyn, how did the cost of that service compare with the cost Don mentioned previously? Sounds like it was probably cheaper? I have this job coming up in the near future and may start asking about this with dive services in the area.

Tom, Don and all, My dive service has the tools to remove and replace a cutlass beating with the boat IN THE WATER. As well, they have the ability to remove the prop as a part of that same job. It's some sort of hydraulic device that presses the old bearing out and pushes the new one in obviously thus the need for the prop to be off. It's a pretty neat tool given that mine took say,30 minutes start to finish right in the slip. Glyn

Last edited:

The big thing about mine was it was stuck more to the shaft than the strut, plus there wasn't room for their tool to push it towards the prop, so they pushed it forward and then cut it off, plus I'm pretty sure there was some time lost going back and forth for parts, discussion with the job supervisor and so on. If everything goes well, it should be just press off, press on and over in a short time. It seems like there might have been some time spent cutting one to the right length too, but they might have found one the correct length. Apparently, 38s have an unusual length. Not really defending them, KKMI has never been cheap, but usually fair.

Don

Don

Cutlass bearing r & r cost.

Ignacio, I can't really say, it was easily 10 to 12 years ago and the fee has long since faded. I can tell you that of the dive services in Marina del Rey where there's a large customer base of over 6,000 boats, my service was the only one at the time that was wiling to invest in the rather steep cost of the equipment. Glyn

Ignacio, I can't really say, it was easily 10 to 12 years ago and the fee has long since faded. I can tell you that of the dive services in Marina del Rey where there's a large customer base of over 6,000 boats, my service was the only one at the time that was wiling to invest in the rather steep cost of the equipment. Glyn

Maine Sail

Member III

Perhpas....

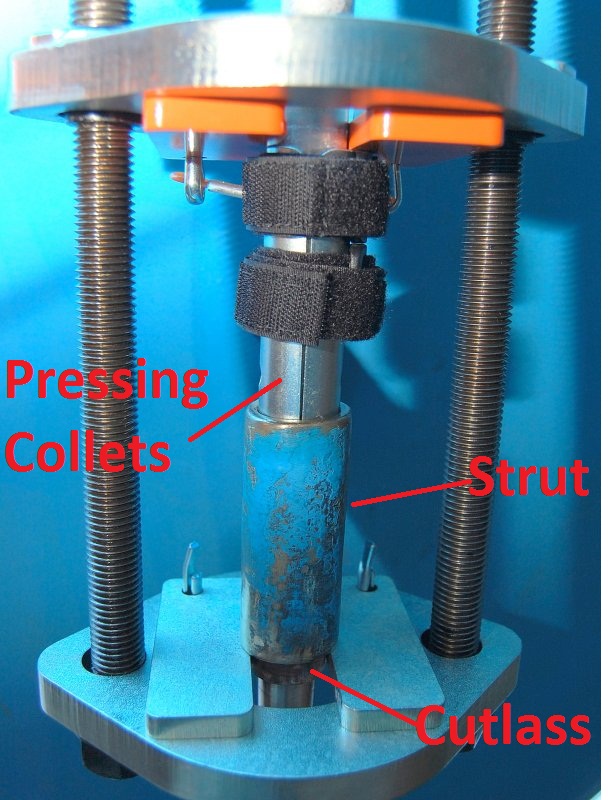

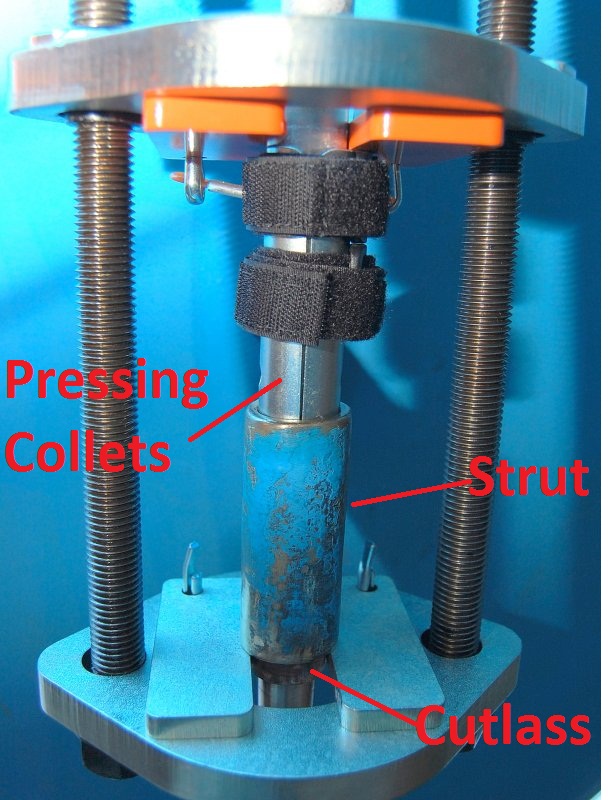

Perhaps you guys, as an association, should do a fund raiser and buy a community Strut-Pro like the Catalina 34 & 36 associations have done. Each member can use it for free then mail it onto the next guy and your only incurred costs are the cost of shipping.

Mine cost about $800.00 but I have the full kit from 7/8" to 3" shafts. I would guess a kit for 7/8" to 1 1/4" would cost significantly less, perhaps $300.00 - $400.00.

Just replaced a bearing on a 41 footer yesterday where the owner spent over $100.00 building his own tool which failed miserably and could not even budge the bearing. The Strut-Pro had it in & out in less than 20 minutes..

Perhaps you guys, as an association, should do a fund raiser and buy a community Strut-Pro like the Catalina 34 & 36 associations have done. Each member can use it for free then mail it onto the next guy and your only incurred costs are the cost of shipping.

Mine cost about $800.00 but I have the full kit from 7/8" to 3" shafts. I would guess a kit for 7/8" to 1 1/4" would cost significantly less, perhaps $300.00 - $400.00.

Just replaced a bearing on a 41 footer yesterday where the owner spent over $100.00 building his own tool which failed miserably and could not even budge the bearing. The Strut-Pro had it in & out in less than 20 minutes..

ChrisS

Member III

A few months ago, ran into a well known local diver, and asked him if replacing the cutlass in the water was possible. He said he had a tool, but needed to know how much exposed shaft my boat had between the hull and the cutlass to see if his tool would fit my boat. He though it'd be an hour and a half job--about 1/2 the price of a haul and launch.