gadangit

Member III

Me again. One of the forward bulkhead chainplates that attach to the lower spreader broke while it was at the riggers. It had been flagged by the eagle eyed surveyor as in need of a closer inspection. I didn't get the whole story, but it broke while it was getting cleaned up to be inspected. I'll post some pics when I get the plate back.

The rigger doesn't like the fact that it is a one piece design that has a flange on the deckside that is very similar to the aft bulkhead "deck hold down" chainplates. He believes that contributed to the metal fatigue and eventual failure. I'm not so certain. There is evidence aplenty of water infiltration at the chainplate and corrosion at bulkhead attachment. And, in theory, it is a 40 year old piece of structural metal.

Can someone confirm that this is an original chainplate design?

If so, should we insist on an exact duplicate? Or is a more traditional straight bar with metal coverplate like the rest going to be sufficient?

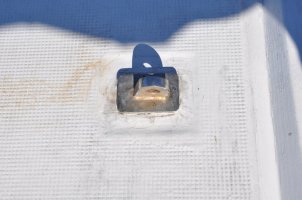

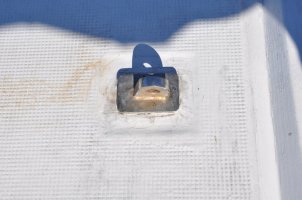

Offending chainplate is location above my elbow.

Offending chainplate, now permanently banished from boat.:0

Similar style chainplate from aft bulkhead that holds deck, (I meant my mangled interpration of Mr. Stevens very clear post.) mangled interpretation from Mr. Stevens. There is clearly a lot less stress on this chainplate, get tested?

mangled interpretation from Mr. Stevens. There is clearly a lot less stress on this chainplate, get tested?

The rigger doesn't like the fact that it is a one piece design that has a flange on the deckside that is very similar to the aft bulkhead "deck hold down" chainplates. He believes that contributed to the metal fatigue and eventual failure. I'm not so certain. There is evidence aplenty of water infiltration at the chainplate and corrosion at bulkhead attachment. And, in theory, it is a 40 year old piece of structural metal.

Can someone confirm that this is an original chainplate design?

If so, should we insist on an exact duplicate? Or is a more traditional straight bar with metal coverplate like the rest going to be sufficient?

Offending chainplate is location above my elbow.

Offending chainplate, now permanently banished from boat.:0

Similar style chainplate from aft bulkhead that holds deck, (I meant my mangled interpration of Mr. Stevens very clear post.)

Last edited: