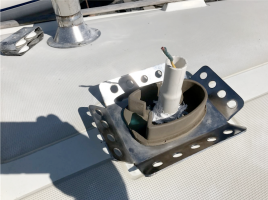

Since I discovered a big leak through the mast step this winter I have been wondering if I should address the slight compression in the area underneath the mast step. With a haulout and mast unstep scheduled in a couple weeks I am starting to think more seriously about it.

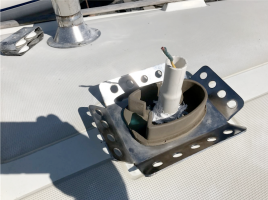

I don't have any photos with the step removed, but there is a slight depression or divot in the cabin top under the starboard aft quarter of the step and mast plate. The underlying material felt sound 5 years ago.

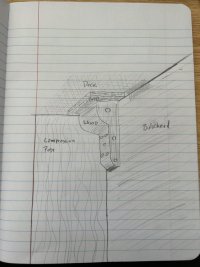

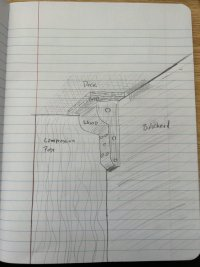

I suspect that water was getting in through the wiring hole for years before I got the boat and rotted a small portion of the bulkhead underneath. The bulkead then slowly deformed under pressure from the mast and lead to the deck compressing in that area. The photo below shows the compression of the bulkhead with some of the plywood that has deformed and delaminated (photo is from the head compartment on the starboard side of the compression post looking forward and towards the port side of the boat). Just to the right outside the photo is sound bulkhead and tabbing (only about an inch of tabbing has been compromised). The compression post appears sound.

So what to do? Easiest of course would be nothing, which may be a valid approach as I am not sure how much further the damage can or will progress. But with the mast down I have an opportunity to jack the deck up and make repairs (the deck won't move much due to the tabbing on the bulkhead). To support the deck in that corner a thick block of teak or something could be attached through the bulkhead and maybe extended over to the compression post as well. This at least might help prevent any further deformation. The wiring bundle is going to be removed and the area sealed completely from the top. I am hoping I will not have to replace the core material under the step but that is possible if it looks like the divot has gotten worse or the step area feels spongy. I am also hoping to avoid overthinking things (my normal modus operandi) as I'm worried I could easily manage to turn this into a major project when a simpler option exists.

Thoughts and opinions welcome.

Thank you.

Doug

I don't have any photos with the step removed, but there is a slight depression or divot in the cabin top under the starboard aft quarter of the step and mast plate. The underlying material felt sound 5 years ago.

I suspect that water was getting in through the wiring hole for years before I got the boat and rotted a small portion of the bulkhead underneath. The bulkead then slowly deformed under pressure from the mast and lead to the deck compressing in that area. The photo below shows the compression of the bulkhead with some of the plywood that has deformed and delaminated (photo is from the head compartment on the starboard side of the compression post looking forward and towards the port side of the boat). Just to the right outside the photo is sound bulkhead and tabbing (only about an inch of tabbing has been compromised). The compression post appears sound.

So what to do? Easiest of course would be nothing, which may be a valid approach as I am not sure how much further the damage can or will progress. But with the mast down I have an opportunity to jack the deck up and make repairs (the deck won't move much due to the tabbing on the bulkhead). To support the deck in that corner a thick block of teak or something could be attached through the bulkhead and maybe extended over to the compression post as well. This at least might help prevent any further deformation. The wiring bundle is going to be removed and the area sealed completely from the top. I am hoping I will not have to replace the core material under the step but that is possible if it looks like the divot has gotten worse or the step area feels spongy. I am also hoping to avoid overthinking things (my normal modus operandi) as I'm worried I could easily manage to turn this into a major project when a simpler option exists.

Thoughts and opinions welcome.

Thank you.

Doug