I'm hauling out my '76 Ericson 23, swing keel model this weekend. This is my first boat / first time hauling out so I have a lot of questions.

She is going on blocks in a local marina (I don't have a trailer).

I'd like her to be as available to work on as possible over the Winter and before I put her back in next Spring.

And she was hauled early this year, painted and had her keel pendant replaced.

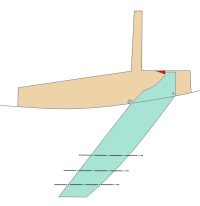

Is it better to have her put on blocks and stands up high so the keel can come all the way down? Put down with the keel pulled all the way up? Or somewhere in between (can't imagine why, but like I said, I'm new to this)?

I don't have any reason to doubt the previous owner painted the bottom and replaced the pendant as claimed, but generally would prefer to keep everything as accessible as possible.

I definitely want to make some repairs / improvements in the cabin and on the deck while she's on the hard, so I'll be climbing around up there if that factors into it.

Are there any particular instructions I should give the marina in terms of where to place the blocks and stands?

Thanks so much for any advice you can give.

She is going on blocks in a local marina (I don't have a trailer).

I'd like her to be as available to work on as possible over the Winter and before I put her back in next Spring.

And she was hauled early this year, painted and had her keel pendant replaced.

Is it better to have her put on blocks and stands up high so the keel can come all the way down? Put down with the keel pulled all the way up? Or somewhere in between (can't imagine why, but like I said, I'm new to this)?

I don't have any reason to doubt the previous owner painted the bottom and replaced the pendant as claimed, but generally would prefer to keep everything as accessible as possible.

I definitely want to make some repairs / improvements in the cabin and on the deck while she's on the hard, so I'll be climbing around up there if that factors into it.

Are there any particular instructions I should give the marina in terms of where to place the blocks and stands?

Thanks so much for any advice you can give.