I also posted this over at plasticclassicforum.com.

I've been thinking about this on and off over the past year, and now is the time to really figure it out. The mast is in reasonably good shape except for the area around the spreaders. There are a bunch of excess holes, and the old spreaders have compressed the mast a bit (a dimple) on both sides. Also, the entire area around the spreaders is slightly compressed a little bit (1/32-1/16" maybe) over the space of about a foot or so. Looks like the spreaders were subject to some violent force at one time. Anyway, the whole area looks a bit weak.

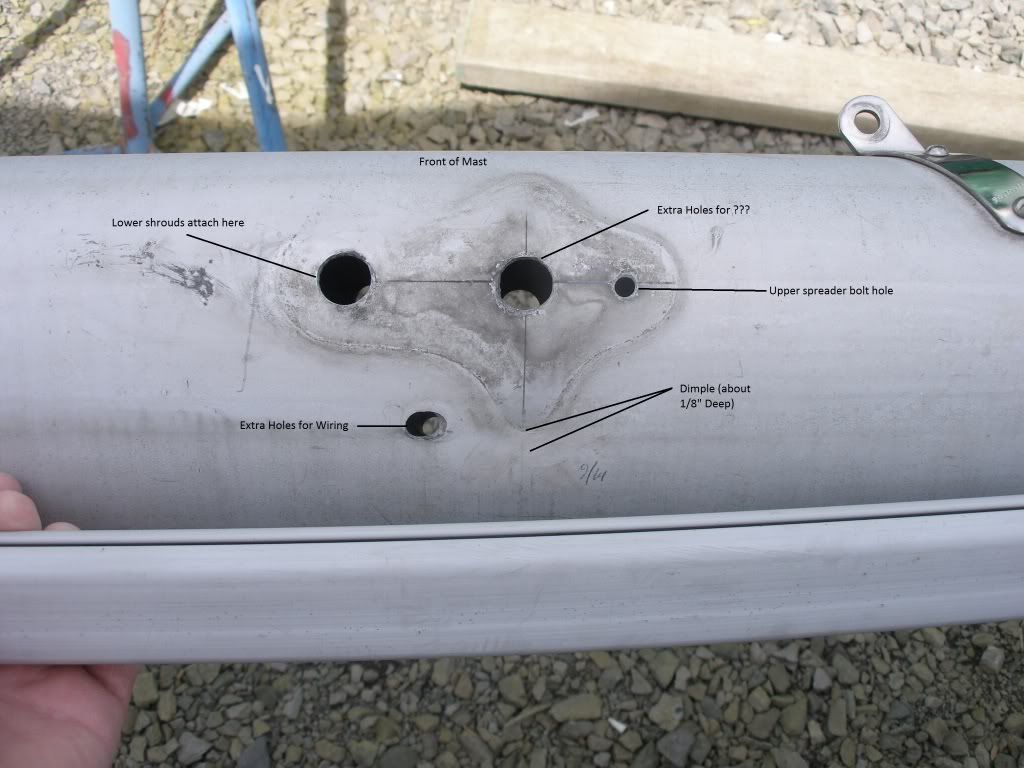

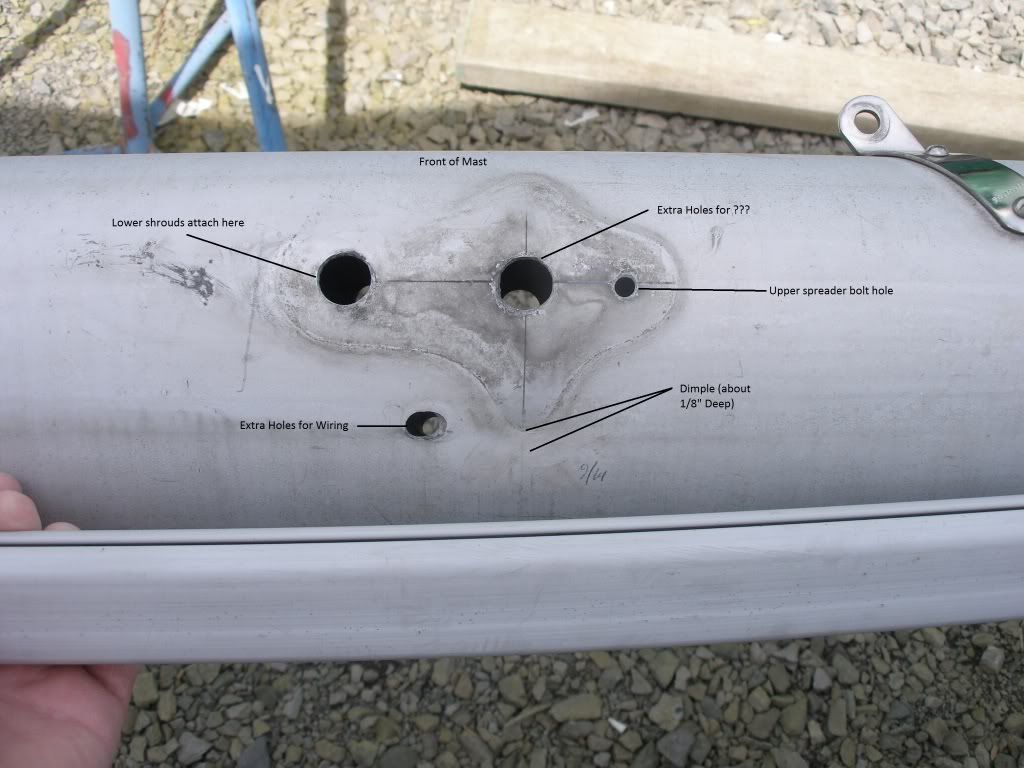

Here is a shot of the area, with some notes on the different features.

Here is the mast profile. The aft wall between the main compartment and the sail track is near the dimpled portion of the mast.

So I have been thinking about putting two big reinforcing patches over each side of the entire affected area and then redrilling only the necessary holes. I have heard that it might be wise to make this in an elongated triangular fashion (tapered up and down the mast) so as not to create a hard point right above or below the patch.

Also, Emerald did a similar repair http://home.comcast.net/~ericson-yachts using a big exterior sleeve, but it sounded like he had some trouble on the installation, so I am not sure that is the easiest way to go.

Any advice would be welcome.

Thanks!

Doug

I've been thinking about this on and off over the past year, and now is the time to really figure it out. The mast is in reasonably good shape except for the area around the spreaders. There are a bunch of excess holes, and the old spreaders have compressed the mast a bit (a dimple) on both sides. Also, the entire area around the spreaders is slightly compressed a little bit (1/32-1/16" maybe) over the space of about a foot or so. Looks like the spreaders were subject to some violent force at one time. Anyway, the whole area looks a bit weak.

Here is a shot of the area, with some notes on the different features.

Here is the mast profile. The aft wall between the main compartment and the sail track is near the dimpled portion of the mast.

So I have been thinking about putting two big reinforcing patches over each side of the entire affected area and then redrilling only the necessary holes. I have heard that it might be wise to make this in an elongated triangular fashion (tapered up and down the mast) so as not to create a hard point right above or below the patch.

Also, Emerald did a similar repair http://home.comcast.net/~ericson-yachts using a big exterior sleeve, but it sounded like he had some trouble on the installation, so I am not sure that is the easiest way to go.

Any advice would be welcome.

Thanks!

Doug

Last edited:

But that said, it's something a couple people can do working together if you're prepared with a good array of clamps etc. Feel free to contact me directly offline if you want to swap numbers and chat some about this.

But that said, it's something a couple people can do working together if you're prepared with a good array of clamps etc. Feel free to contact me directly offline if you want to swap numbers and chat some about this.