You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

89' E34 I'll be going to see this week, curious what others think.

- Thread starter ofshore74

- Start date

ofshore74

Member III

I’ve been locked in a cruel struggle with my Edson pedestal for the better part of a week (see my recent posting in the M&M forum) so I’d like to chime in here.

On my 1988 E34, the raised cockpit floor is very solid. It’s about 1 1/4 inches thick, and half of that is plywood. You can see that in the photo, where the bronze plate that backs the pedestal (and holds the steering sheaves) has been removed. The other photo shows the corner area. It’s heavily reinforced.

I suppose it is possible that there is structural damage and/or a rotten core problem, but maybe the four bolts that hold down the pedestal are loose, or the bedding material around the base has deteriorated. Is the deck really flexing? I can’t tell from the videos.

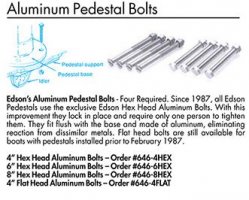

Let me warn you about those 1/2-13 bolts. They are made of aluminum and, if they are at all corroded, will break if you try to turn the nuts. That’s what happened to me and I had to drill them out from the top. Unpleasant job. Stupidly, the hex heads are captured in the pedestal base casting, so you can’t grab them with a wrench or use a screw extractor. I assume that Edson chose aluminum to avoid interference with the compass. Anyway - beware!

BTW, if you are considering the boat in Blaine, I would say that the asking price is about right (assuming they will come down 10%). I would drop and retrieve the full length of the anchor rode with that windlass (a couple of times at least), and also run he heater for a while. The engine hours are VERY low, which could be good or bad, depending.

This is helpful thank you. Will definitely check out your other thread. Forgot to mention, I took the tip of a swiss army blade and inserted it where I had access to the plywood core under the pedestal base and noticed one side was not as solid as the other but it wasn't black or rotted. I think what happened and someone said this before, is a bad bedding job causing water to leak down the bolt on one side of the pedestal stand and softened it which caused this flex. But I won't know for sure until I have a professional look at it.

Afrakes

Sustaining Member

NaCl

Once you introduce long term exposure to moisture and NaCl things get interesting. Stainless steel, flat head machine bolts were used to secure the Orion pedestal on the 81' 28+ I dismantled. There definitely was a lot of corrosion to the aluminum base. The bolts popped right out when struck from below. Some things about the installation indicated that it was not installed by the factory. Or someone at the factory was really loaded when the work was done.

Once you introduce long term exposure to moisture and NaCl things get interesting. Stainless steel, flat head machine bolts were used to secure the Orion pedestal on the 81' 28+ I dismantled. There definitely was a lot of corrosion to the aluminum base. The bolts popped right out when struck from below. Some things about the installation indicated that it was not installed by the factory. Or someone at the factory was really loaded when the work was done.

Interesting. Aluminum, so no dissimilar metals issues. Recessed heads, so one person can tighten them.

Arguments against both are available.

Or someone at the factory was really loaded when the work was done.

well....it *was* southern California in the 80s....

ofshore74

Member III

Offer made. Engine discoveries.

So it sounds like the paperwork will be sorted out in a week to finalize the offer made on the 89' 34-2, for now it was verbally accepted. Following that sea trial, survey, engine inspection, rigging who knows it may even be my boat.

Out of curiosity I had one more peek at the engine (photos below) prompted by someone who said I should check out the engine mounts. There is certainly corrosion on one, and I can see that the spraying (aka dripping) at the shaft seal, which was perhaps too loose and not monitored/maintained, has made itself known all over the back of the engine in the form of flaking, bubbling and corrosion. So that's one big fat thing that irks me.

The second thing is that as I crouched down in front of the engine with my camera, I noticed a small hairline crack around the perimeter at the base (the Tri-axel?) where the engine mounts on the port-side. I have heard that any cracking of any kind, especially where it's structural is a bad thing. And thankfully I have not seen it anywhere else on this boat. But just to be sure it was a crack and not dirt, I ran my fingernail over it could feel the hairline crack, which appears to wrap around one side. Does anyone have any thoughts on a repair like this, or if I'm in for an additional 5k that I hadn't accounted for?

Obviously the survey will tell me more but thought I'd share it here first so that if there is something obvious I won't be surprised when it comes up.

https://drive.google.com/folderview?id=0Bx6tzmnoism-RDZaTlRMTUJ0M2M&usp=sharing

So it sounds like the paperwork will be sorted out in a week to finalize the offer made on the 89' 34-2, for now it was verbally accepted. Following that sea trial, survey, engine inspection, rigging who knows it may even be my boat.

Out of curiosity I had one more peek at the engine (photos below) prompted by someone who said I should check out the engine mounts. There is certainly corrosion on one, and I can see that the spraying (aka dripping) at the shaft seal, which was perhaps too loose and not monitored/maintained, has made itself known all over the back of the engine in the form of flaking, bubbling and corrosion. So that's one big fat thing that irks me.

The second thing is that as I crouched down in front of the engine with my camera, I noticed a small hairline crack around the perimeter at the base (the Tri-axel?) where the engine mounts on the port-side. I have heard that any cracking of any kind, especially where it's structural is a bad thing. And thankfully I have not seen it anywhere else on this boat. But just to be sure it was a crack and not dirt, I ran my fingernail over it could feel the hairline crack, which appears to wrap around one side. Does anyone have any thoughts on a repair like this, or if I'm in for an additional 5k that I hadn't accounted for?

Obviously the survey will tell me more but thought I'd share it here first so that if there is something obvious I won't be surprised when it comes up.

https://drive.google.com/folderview?id=0Bx6tzmnoism-RDZaTlRMTUJ0M2M&usp=sharing

Last edited:

I'm guessing the crack in the gelcoat is not a problem. It will be interesting to hear what the surveyor says.

The engine looks pretty typical in the photos. I don't recognize the component in the second picture (xxx90.jpg) but the tube looks rusted past the limit.

BY the way, as you go through the surveyor exercise examine closely the forestay and backstay tangs, which can be hard to inspect without a dinghy. (I recently discovered a large crack in my backstay tang after turning the boat around in the slip). Same with the stays and turnbuckles and fittings. Any crack no matter how small means replacement. A magnifying glass helps.

The engine looks pretty typical in the photos. I don't recognize the component in the second picture (xxx90.jpg) but the tube looks rusted past the limit.

BY the way, as you go through the surveyor exercise examine closely the forestay and backstay tangs, which can be hard to inspect without a dinghy. (I recently discovered a large crack in my backstay tang after turning the boat around in the slip). Same with the stays and turnbuckles and fittings. Any crack no matter how small means replacement. A magnifying glass helps.

ofshore74

Member III

I don't recognize the component in the second picture (xxx90.jpg) but the tube looks rusted past the limit.

BY the way, as you go through the surveyor exercise examine closely the forestay and backstay tangs, which can be hard to inspect without a dinghy. (I recently discovered a large crack in my backstay tang after turning the boat around in the slip). Same with the stays and turnbuckles and fittings. Any crack no matter how small means replacement. A magnifying glass helps.

Thanks. Now you've got me on a wild goose hunt for the universal engine manual to find out what that is! And thanks for the heads up about the standing rigging will bring a fine tooth comb.

Engine puzzlement

If you rotate the picture 90 degrees, it looks like the bottom of the dip stick tube where it bolts to the pan.

Loren

If you rotate the picture 90 degrees, it looks like the bottom of the dip stick tube where it bolts to the pan.

Loren

ofshore74

Member III

If you rotate the picture 90 degrees, it looks like the bottom of the dip stick tube where it bolts to the pan.

Loren

I think you're right! Here's the two photos I didn't include in the photo sequence with your 90º suggestion, in which case I would most certainly need a new dip stick tube:

Attachments

ofshore74

Member III

surveyors and process

The latest development in this boat purchase is finding a surveyor that will do a border crossing (found one [check]) lining up a marine mechanic for an engine survey and rigger for an inspection of standing rigging is next on the list.

In terms of the order one surveys a boat, I'd like for the boat to be in slings overnight to check the keel/hull joint for leaking -- I assume this would happen first so that the surveyor can inspect the bottom, then we put her back in the water for the rest of the survey, then engine survey, rigging survey. Does this order sound about right?

The surveyor I found is brutally honest and tells it like it is. And is one of the busiest in the area which is why I think he's the right choice. But he also said in our initial conversation that I'd probably need to replace the engine soon on a boat this age -- I found this statement a bit blind considering he hasn't seen the boat yet. I guess my question is, are surveyors the ones who pour a cold bucket of water over your head so you don't get your head or heart set on something? My guess is yes. In which case I'm stating the obvious.

The latest development in this boat purchase is finding a surveyor that will do a border crossing (found one [check]) lining up a marine mechanic for an engine survey and rigger for an inspection of standing rigging is next on the list.

In terms of the order one surveys a boat, I'd like for the boat to be in slings overnight to check the keel/hull joint for leaking -- I assume this would happen first so that the surveyor can inspect the bottom, then we put her back in the water for the rest of the survey, then engine survey, rigging survey. Does this order sound about right?

The surveyor I found is brutally honest and tells it like it is. And is one of the busiest in the area which is why I think he's the right choice. But he also said in our initial conversation that I'd probably need to replace the engine soon on a boat this age -- I found this statement a bit blind considering he hasn't seen the boat yet. I guess my question is, are surveyors the ones who pour a cold bucket of water over your head so you don't get your head or heart set on something? My guess is yes. In which case I'm stating the obvious.

Does this order sound about right?

It may be a matter of the surveyor's preferences.

In my purchase, the surveyor wanted the mechanical inspection and rig inspection done before he arrived, so that he would have those findings in hand when he started his inspection of the boat.

He also wanted the bottom cleaned before the boat came out of the water.

$.02

ofshore74

Member III

It may be a matter of the surveyor's preferences.

Thanks for that, checking on his preferences.

What the surveyor actually said...well, it is very unlikely your engine needs to be replaced on a 1989 boat.

My experience with surveyors has been that they do not like to kill sales. It's bad for business, and no broker would recommend them.

They're there to discover big stuff, and they will miss most of the small stuff, and may put in some eccentric stuff while they're at it.

The insurance company will want most of what they note fixed, which is a good reason to ask they not write it down, which they may agree to if it's not a safety issue.

Personally, I would ask this surveyor how many 1989 boats he has recommended new engines for, and some further context for what he's saying.

My experience with surveyors has been that they do not like to kill sales. It's bad for business, and no broker would recommend them.

They're there to discover big stuff, and they will miss most of the small stuff, and may put in some eccentric stuff while they're at it.

The insurance company will want most of what they note fixed, which is a good reason to ask they not write it down, which they may agree to if it's not a safety issue.

Personally, I would ask this surveyor how many 1989 boats he has recommended new engines for, and some further context for what he's saying.

They're there to discover big stuff, and they will miss most of the small stuff, and may put in some eccentric stuff while they're at it.

My surveyor got down to the level of "the lifeline gate needs to be taped".

Of course that's *all* he found that needed attention. I think he was desperate to find something he could write in his report.

And then the seller ran out and fixed it before the surveyor had the time to get even *that* written up....

;-)

Last edited:

ofshore74

Member III

This particular surveyor is saying that he doesn't get a lot of calls from brokers because brokers don't like it when he points stuff out to buyers. I guess he kills sales? He's the cold bucket of water type but if he finds out a boat is a nightmare it'll could be money well spent. I should find out in three weeks.My experience with surveyors has been that they do not like to kill sales. It's bad for business, and no broker would recommend them.

ofshore74

Member III

Personally, I would ask this surveyor how many 1989 boats he has recommended new engines for, and some further context for what he's saying.

Thanks for that and I asked him this. It was a long answer but he couldn't give exact cases. Mentioned do an oil sample. Said something like, most boats with engines of this vintage will need an overhaul of some capacity or repower, and most engines last 30 years.

In the end I feel like he has been trying to prepare me for major expenses getting into a boat, with all the repairs I found and think that it might need I gave him my list. And he told me I offered too much for it (which I don't believe I did at just over 40k) and should be prepared for 40k more to bring it up to good condition. I guess he thinks I would be pulling up to a marina and saying to the foreman "hey boys! she's all yours send me the bill!"

Well, It's true that we pay for his opinions. He's certainly given away a bucketful for free.

Value is calculated on have the work done with labor hours having a cost.

This is exactly what he is paid to think.

A surveyor would never calculate the cost of parts and have a $0 value for labor time. That would not be realistic in the valuation of a boat. The only way to calculate the value is what would it take to have competent professionals bring the boat up to good shape, or condition (this has a definition, which is all installed systems functional, no safety issues, and a similar appearance to sister ships that are on the market at the time. Anything which does not fit this criteria, is deemed necessary to repair or replace. The amount to have a competent local yard fix or replace the broken, or missing items, is deducted from the value off the boat off of the fair market price of the boats in comparison to other vessels.

How else would the value of a boat be established? You noted earlier that you thought that maybe surveyors where there to kill deals and crush dreams. They are there in a capacity as a disinterested 3rd party with experience the field. If reality and dreams do not match, then indeed the surveyor may seem like a deal or dream crusher. The idea that the good surveyors are recommended by brokers is in my experience absolutely not true. The broker wants the worst surveyor that they can possibly get you to take. They get the highest amount of money and the seller and the broker get the most in their wallet. The surveyor is hired by you, and works for you. He is the only person on your side in buying a boat. If he seems to be harshing your mellow, remember he is YOUR MAN, and the only person between you and a good fleecing.

Guy

I guess he thinks I would be pulling up to a marina and saying to the foreman "hey boys! she's all yours send me the bill!"

This is exactly what he is paid to think.

A surveyor would never calculate the cost of parts and have a $0 value for labor time. That would not be realistic in the valuation of a boat. The only way to calculate the value is what would it take to have competent professionals bring the boat up to good shape, or condition (this has a definition, which is all installed systems functional, no safety issues, and a similar appearance to sister ships that are on the market at the time. Anything which does not fit this criteria, is deemed necessary to repair or replace. The amount to have a competent local yard fix or replace the broken, or missing items, is deducted from the value off the boat off of the fair market price of the boats in comparison to other vessels.

How else would the value of a boat be established? You noted earlier that you thought that maybe surveyors where there to kill deals and crush dreams. They are there in a capacity as a disinterested 3rd party with experience the field. If reality and dreams do not match, then indeed the surveyor may seem like a deal or dream crusher. The idea that the good surveyors are recommended by brokers is in my experience absolutely not true. The broker wants the worst surveyor that they can possibly get you to take. They get the highest amount of money and the seller and the broker get the most in their wallet. The surveyor is hired by you, and works for you. He is the only person on your side in buying a boat. If he seems to be harshing your mellow, remember he is YOUR MAN, and the only person between you and a good fleecing.

Guy

Last edited: