My question regards the ever-more-popular very small wires in our lives. I never got the memo on how to deal with them.

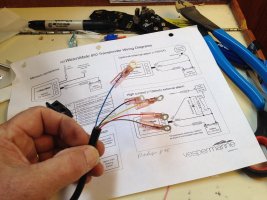

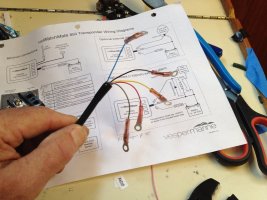

For example, I have in hand a six-foot instrument cable (for an antenna splitter) containing seven wires of 22GA or smaller. Red and black will travel four feet to get to the panel. VArious NMEA wires only travel half that distance. Now what?

Maybe there's a tool I don't own (yet) to strip the entire cable sheath without damaging these tiny wires. Certainly can't strip the sheath by hand without nicking the wires.

If I do strip the sheath off the cable, I'll have seven six-foot-long 22GA wires. Run those through bulkheads to fight for space with the wires already there?

Doesn't seem right. Not robust. Do they even make wire hangers for 22GA?

Or are we supposed to just cut the sheath off short and butt-connect 16GA to each tiny strand, for a bigger wire? 16GA is the "minimum" the manu recommends when "extending" its tiny comm/power wires.

In which case, why give me six feet of it?

What am I missing here? Do you strip bundled 22GA? Should you?

Do I need some dedicated miniature-wire connector/terminal block?

Thanks--this ain't in Nigel Calder.

For example, I have in hand a six-foot instrument cable (for an antenna splitter) containing seven wires of 22GA or smaller. Red and black will travel four feet to get to the panel. VArious NMEA wires only travel half that distance. Now what?

Maybe there's a tool I don't own (yet) to strip the entire cable sheath without damaging these tiny wires. Certainly can't strip the sheath by hand without nicking the wires.

If I do strip the sheath off the cable, I'll have seven six-foot-long 22GA wires. Run those through bulkheads to fight for space with the wires already there?

Doesn't seem right. Not robust. Do they even make wire hangers for 22GA?

Or are we supposed to just cut the sheath off short and butt-connect 16GA to each tiny strand, for a bigger wire? 16GA is the "minimum" the manu recommends when "extending" its tiny comm/power wires.

In which case, why give me six feet of it?

What am I missing here? Do you strip bundled 22GA? Should you?

Do I need some dedicated miniature-wire connector/terminal block?

Thanks--this ain't in Nigel Calder.