Cavity Filling / Lead Keel Dentistry

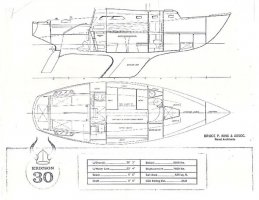

Thanks for the drawing, that is exactly what I have. Now what was interesting when I stripped the bottom paint and sanded the bottom a couple of years ago I found that the trailing edge were simply layers of glass converging from both sides of the keel and to my dismay they were delaminating. I could stick a knife in between them. No wonder my keel kept filling up with water. If I added lead to that space I was going to grind off the paint again and reinforce it even more than I just did. I wonder what a 5 gal bucket of lead pellets would weigh? I guess I could bring a scale to my local gun shop and pack a bucket with bags of pellets to get an idea. I don't think it would be near enough to make a difference.

Not sure why you believe that the boat needs any extra ballast... but low down is the place for it.

Since other owners here have commented in the past about adding some thickened epoxy to the bottom of the aft keel cavity to forestall any water seepage from a grind-y grounding, perhaps you could:

1) do all the repair and reinforcement on the outside so that the trailing edge is secure and solid, and then

2) fill, in small batches, from the inside with epoxy and lead shot. Maybe bring it up halfway or so? Further?

Do you have good access to that cavity from the top to be sure it is clean and dry for new resin to bond to?

Interesting project idea.

Be sure to post up photos of the work as it progresses.

Fair winds and Non-Tsunanious seas,

Loren