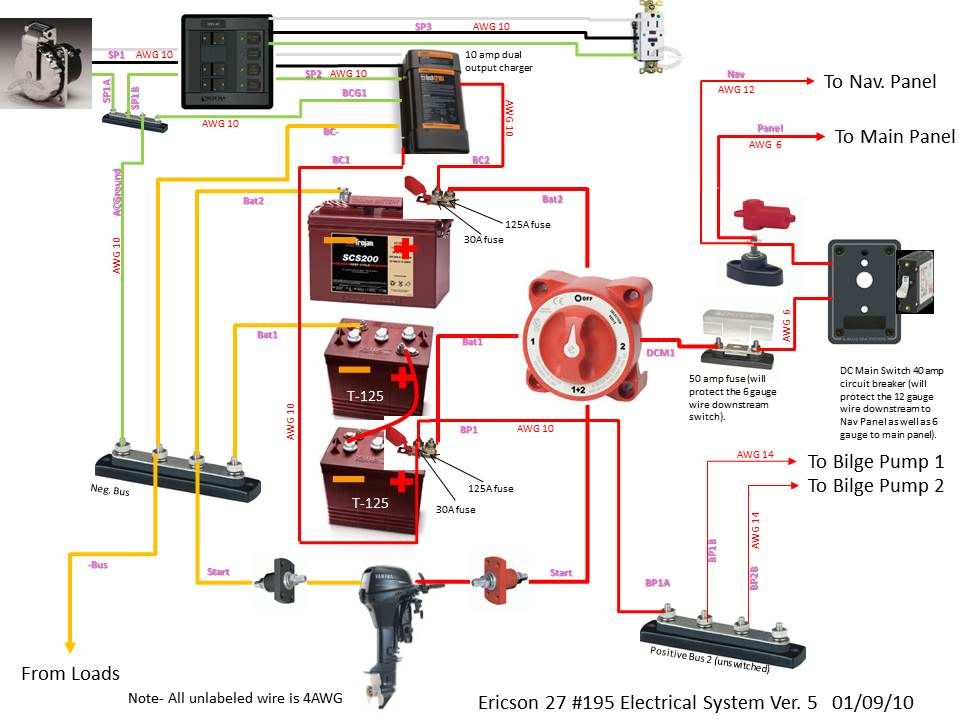

What MaineSail said. Yamaha have been making those High Thrust 9.9's for years. They must be bolted on the transoms of thousands of Catalina 27s, Hunters, etc. From the schematic it looks like you've got the on-motor starter button model. Surely to heavens they have internal protection to keep the charging and ignition curcuits safe from starting currents. Ignition relays, diodes, fuses, that kind of thing.

The Yamaha can take a wave over the powerhead (at a harbour entrance, say, when raising/lowering your main, in blowy conditions), die, then restart without any ill effects. I know because I've done it. Tough motors. Well marinised.

With only one (heavy gauge) wire in and out of the motor for starting and charging duties you have to rely on the engine builder. You can't fuse for both. Or can you?

Interesting thread. Those of us out of our depth are enjoying it. Thanks to all involved !

Rob L.

Vancouver

E34

The Yamaha can take a wave over the powerhead (at a harbour entrance, say, when raising/lowering your main, in blowy conditions), die, then restart without any ill effects. I know because I've done it. Tough motors. Well marinised.

With only one (heavy gauge) wire in and out of the motor for starting and charging duties you have to rely on the engine builder. You can't fuse for both. Or can you?

Interesting thread. Those of us out of our depth are enjoying it. Thanks to all involved !

Rob L.

Vancouver

E34