1981 E38 anchor locker / bow cleats advice (PICTURES)

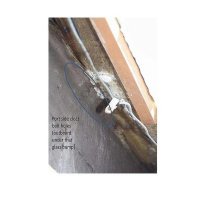

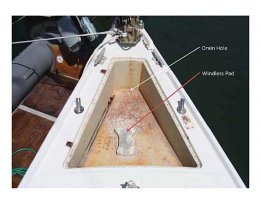

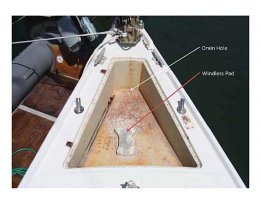

So as most projects go I started this with the intent of finishing in a day. I wanted to replace the forward bow cleats and re-bed all forward hardware. The PO has installed a custom aluminum bracket under the weak anchor pan. He wanted it to be extra stout for a below deck windless. It is a pretty well thought out and well built bracket. He exclaimed that in order to tear out the windless the entire bow would have to come off. The forces he didn't fully think out was the downward forces of 150' 5/16 chain, 400' if rode, the weight of the windless (20-30lbs) and the weight of the bracket (30-40lbs). All this weight over the last 20-30 years of beating has pulled down on the cleats and stanchion bases he used to connect the bracket.

After digging out the thin anchor pan, I was able to get to the bolts for the bracket and loosen and remove it. Just to find out while removing all the hardware that the outer two bolts on both cleats where under the fiber glass. I have read a few posts from several years ago about this but the died out without much conversation.

Please look through the photos I have provided and give thoughts, ideas, and what you would do's. I'm a bit worried to cut into the fiberglass, I'm not happy with the bracket pulling down on the cleats and stanchion bases compressing the deck, and I'm not sure if I can properly mount the new cleats over the divots created by the old ones.

My thoughts so far are to try to get the outboard bolts out from topside hoping the fiber will hold the nut underneath. Then clean and re-bed into the existing hole. I'm not completely comfortable with this method since I do use these cleats often for anchoring and need them to be well secured. It makes me nervous to not know what is behind the glass.

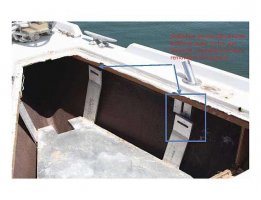

In regards the bracket, I'm thinking of taking threads advice and installing marine ply on the bottom and glassing it in. I do not intend to remount the windless since it is virtually useless in such a shallow pan. I need the added space for the two bow anchor chains and rode and don't need the additional weight of the windless. With this said, I haven't ruled out cutting a hole for the chain and rode to drop all the way down into the bow locker. Not sure about how to keep deck wash out of the bilges though since the bow lock doesn't drain out but in.

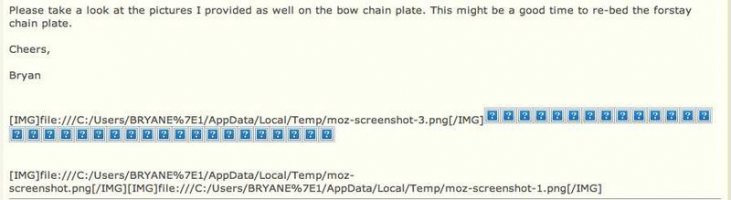

Please take a look at the pictures I provided as well on the bow chain plate. This might be a good time to re-bed the forstay chain plate.

Cheers,

Bryan

So as most projects go I started this with the intent of finishing in a day. I wanted to replace the forward bow cleats and re-bed all forward hardware. The PO has installed a custom aluminum bracket under the weak anchor pan. He wanted it to be extra stout for a below deck windless. It is a pretty well thought out and well built bracket. He exclaimed that in order to tear out the windless the entire bow would have to come off. The forces he didn't fully think out was the downward forces of 150' 5/16 chain, 400' if rode, the weight of the windless (20-30lbs) and the weight of the bracket (30-40lbs). All this weight over the last 20-30 years of beating has pulled down on the cleats and stanchion bases he used to connect the bracket.

After digging out the thin anchor pan, I was able to get to the bolts for the bracket and loosen and remove it. Just to find out while removing all the hardware that the outer two bolts on both cleats where under the fiber glass. I have read a few posts from several years ago about this but the died out without much conversation.

Please look through the photos I have provided and give thoughts, ideas, and what you would do's. I'm a bit worried to cut into the fiberglass, I'm not happy with the bracket pulling down on the cleats and stanchion bases compressing the deck, and I'm not sure if I can properly mount the new cleats over the divots created by the old ones.

My thoughts so far are to try to get the outboard bolts out from topside hoping the fiber will hold the nut underneath. Then clean and re-bed into the existing hole. I'm not completely comfortable with this method since I do use these cleats often for anchoring and need them to be well secured. It makes me nervous to not know what is behind the glass.

In regards the bracket, I'm thinking of taking threads advice and installing marine ply on the bottom and glassing it in. I do not intend to remount the windless since it is virtually useless in such a shallow pan. I need the added space for the two bow anchor chains and rode and don't need the additional weight of the windless. With this said, I haven't ruled out cutting a hole for the chain and rode to drop all the way down into the bow locker. Not sure about how to keep deck wash out of the bilges though since the bow lock doesn't drain out but in.

Please take a look at the pictures I provided as well on the bow chain plate. This might be a good time to re-bed the forstay chain plate.

Cheers,

Bryan

Last edited: