Sven

Seglare

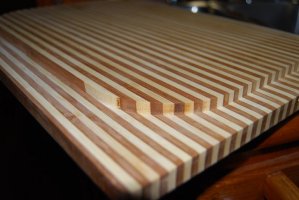

I just routed a bamboo cutting board so that it should just fit over one of the sinks with a lip keeping it in place.

What I want to do when we've taken it down for a sanity fit on Senta is to also rout a groove around/inside the edge leading to a hole in the board so that water on the cutting board is channeled into the sink underneath rather than onto the surrounding counter top.

What I am wondering is how to guide the router along the groove and keep it from veering either left or right ? The only thing I can think of is to build a guide/jig that constrains both sides of the router plate and I'm wondering if there is some other trick I'm missing ?

I will need the same straight routing when I finally get around to routing hatches in the cabin sole for fuel and water inspection ports (yikes!).

-Sven

What I want to do when we've taken it down for a sanity fit on Senta is to also rout a groove around/inside the edge leading to a hole in the board so that water on the cutting board is channeled into the sink underneath rather than onto the surrounding counter top.

What I am wondering is how to guide the router along the groove and keep it from veering either left or right ? The only thing I can think of is to build a guide/jig that constrains both sides of the router plate and I'm wondering if there is some other trick I'm missing ?

I will need the same straight routing when I finally get around to routing hatches in the cabin sole for fuel and water inspection ports (yikes!).

-Sven